Introduction

Over the years, Apple MacBook's powerful pressure and haptic feedback and the touchpad have always been popular with consumers.

The touchpad of laptops has undergone generations of technological change. The MacBook series has adopted the design of module integration, multi-touch, force touch and haptic feedback since 2015.

In fact, only the MacBook series and a few Windows laptops support pressure and haptic feedback so far. Even Windows laptops with pressure and haptic feedback mostly use a single-stage pressure sensor and haptic feedback, which is not very responsive and lacks the support of the application and a good experience.

At the CES 2022, some Windows laptops with integrated pressure sensors and multi-dimensional input were released and received widespread attention and discussion from consumers.

Chipsea Technologies is the first to launch the HapticPad, which is comparable to the Force Touch touchpad of the MacBook.

HapticPad

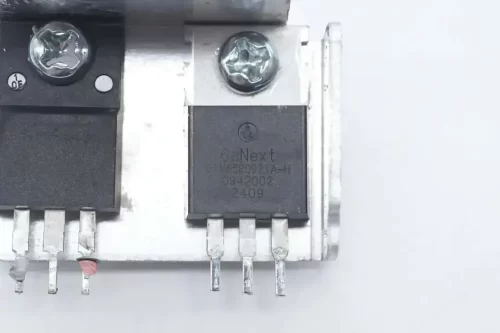

The HapticPad provided by Chipsea is based on its nearly 20 years of high precision ADC and high-reliability MCU technology, integrating capacitive haptic control, pressure sensor and haptic feedback components, supporting a chipset and algorithm of "Turn Key" solution.

The pressure sensor chip integrated the 32-bit MCU with built-in 60KB Flash and 16KB SRAM. The pressure detection resolution can reach 0.1g (0.0035 oz) by the 9-channel 16-bit high precision ADC. With the pressure sensor, any single finger, two fingers, and even the stylus can replace the traditional mouse.

HapticPad has a high sensitivity of 0.1g (0.0035 oz) pressure detection resolution through the 16-bit high precision ADC.

HapticPad has a mature algorithm solution that supports precise force sensor, global sensing press, smooth control and haptic feedback, which can deeply meet the manufacturers' laptop product's development from the hardware level and replace the mouse, bringing users a more intelligent and comfortable haptic experience.

HapticPad's module sets up multiple sensors to meet the needs of different applications and is suitable for various products, and can accommodate various input modes.

The chip supports multi-finger gestures to match the operating system, up to ten fingers tracking. At the same time, it has built-in hardware noise reduction and waterproof circuitry. For laptop manufacturers, it can reduce the internal footprint of the product to improve performance and reduce costs while having a slimmer and lighter product.

In addition, the HapticPad has the advantages of high linearity, consistency, reliability, and stability.

It can achieve multiple levels of haptic control. For example, suppose different load forces are applied to the global touchpad. In that case, HapticPad can achieve high linearity of signal output, and with the vibration motor to attain accurate and intelligent 3D haptic feedback, thus bringing a comfortable and natural user experience.

Opportunities

At present, with the development and overall cost optimization of the new touchpad technology of pressure and haptic feedback, Windows laptops are facing the opportunity to upgrade the key components.

As China's leading force touch solution supplier, the Chipsea HapticPad for the laptop market uses the "piezoresistive membrane + linear motor" technology, compared to the Apple "strain gauge + linear motor" technology solution. The HapticPad is easier to produce and install.

Summary of ChargerLAB

Chipsea Technologies is the first to launch the HapticPad, which is comparable to the Force Touch touchpad of the MacBook.

The HapticPad provided by Chipsea is based on its nearly 20 years of high precision ADC and high-reliability MCU technology, integrating capacitive haptic control, pressure sensor and haptic feedback components, supporting a chipset and algorithm of "Turn Key" solution.

At present, with the development and overall cost optimization of the new touchpad technology of pressure and haptic feedback, Windows laptops are facing the opportunity to upgrade the key components. The HapticPad is easier to produce and install.