Introduction

Razer is a well-known gaming hardware manufacturer focusing on gaming peripherals and the Blade series of laptops. Today, we will take apart the power adapter for Razer‘s Blade laptops.

This adapter can be up to 280W, providing sufficient and stable power supply for high-performance processors and graphics cards, bringing an excellent gaming experience. It integrates GaN transistors from GaN Systems. So, its size is much smaller than traditional laptop power adapters.

GaN Systems was established in Ottawa, Canada in 2008, and its products are popular with customers in different industries. ChargerLAB also took apart the Apple 140W GaN charger in our YouTube channel and found two GaN Systems transistors inside, which further reflects the high-quality of GaN Systems’ products for being an Apple supplier. The GaN transistor from GaN Systems is also adopted by Alienware's 240W GaN Charger.

Product Appearance

This adapter adopts the traditional design and looks like a brick. The braided power cord is detachable and fixed with a rubber cable tie.

The Razer logo is at the top.

All spec info is at the bottom. It has been qualified to CCC, CE, UKCA, UL, PSE, KC, and other standards. The manufacturer is Honor Electronic.

The model of this adapter is RC30-042, which supports an input of 100-240V~50/60Hz 4A and an output of 19.5V 14.36A.

Here is the input socket.

The output end is on the other side. The cable is parallel to the adapter for ease of use. There is also an LED indicator next to it.

After removing the cable, this is not a USB-C connector, but a proprietary connector for Razer laptops.

The length is 163.54mm (6.44 inches).

The width is 69.96mm (2.75 inches).

And the thickness is 24.66mm (0.97 inches).

The length of the output cable is about 2 m (6’ 6.74”).

The diameter of the cable is 5.79mm (0.22 inches).

And the weight is about 654g (1.44 lb).

Teardown

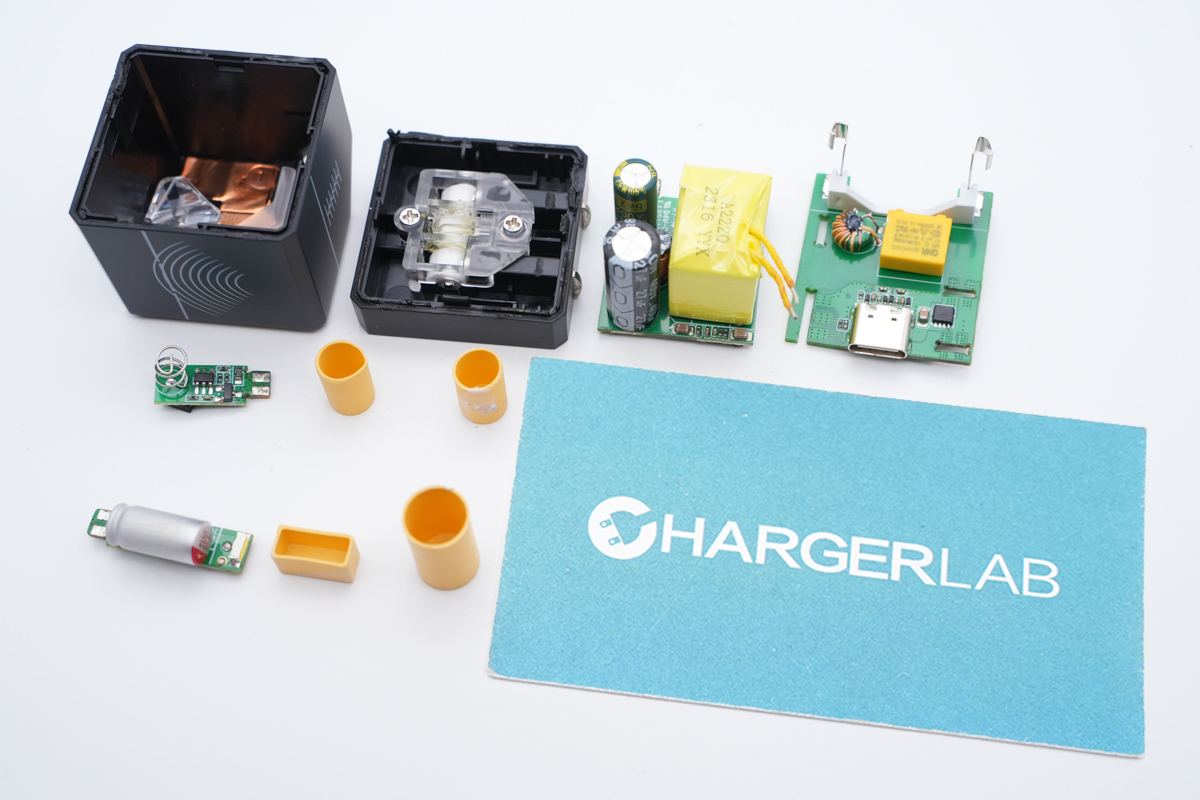

After the brief introduction and measurement of Razer’s power adapter, let’s take it apart and check the internal components, including the GaN components.

Pry along the gap to remove the back cover. The internal PCBA module is wrapped with pure copper heat sink.

Here is the solder joint.

The silicone adhesives are applied to the heat sink to enhance heat dissipation.

Here are the output wires. Two white wires are positive, the black wire is negative, and the thin red wire is used for power identification.

The back of the PCBA module is also wrapped with pure copper heat sink.

The vernier caliper shows the length of the PCBA module is 156.51mm (6.16 inches).

The width is about 65.84mm (2.59 inches).

The thickness is about 20.48mm (0.8 inches).

Remove the heat sink. We can see the PFC boost inductor and resonant inductor. The LLC transformer is covered with silicone adhesives, used to dissipate heat.

A small vertical PCB is soldered on the main PCB.

Some bridge rectifiers and PFC boost MOSFETs are soldered on it.

Five solid capacitors, in the bottom corner, are connected in parallel for output filtering.

The white foam behind the input socket acts as a buffer.

Take a closer look at the input socket.

Here is the front of the PCBA module. The solid output capacitor is in the upper left corner. The electrolytic capacitors are in the lower left corner. The LLC transformer is next to the capacitor. And the resonant inductor is on the right side of the transformer. The PFC boost inductor is below the resonant inductor. The input EMI filter circuit is on the right.

The back of the module is much simpler. The largest component is the PFC boost inductor. A 2-in-1 controller on the right side can control the PFC boost and LLC circuit. The secondary synchronous rectifier circuit is in the upper right corner. And we can also see two optocouplers.

ChargerLAB found it adopts the PFC circuit and LLC topology. And the controller can output the fixed voltage to charge the laptop.

Let’s introduce every single component.

The input filter circuit consists of a fuse, common mode choke, and safety X2 capacitor.

The input fuse is from CONQUER and is used for input overcurrent protection.

6.3A 250V.

The common mode choke is green and is wound with insulated wires.

From the side, we can see the safety X2 capacitor, common mode choke, electrolytic capacitor, resonant inductor, and transformer.

The safety X2 capacitor is 0.47μF.

The second common choke is wrapped with tape for insulation.

Six bridge rectifiers, two GaN chips, and a PFC boost rectifier are soldered on the small PCB.

Those six bridge rectifiers can form three full-bridge circuits to dissipate heat evenly, marked with MB30JL. The Rated current is 3A.

The filter capacitor is from Surong, and the specification is 1μF 450V.

The close-up of the output filter inductor.

Those two film capacitors are from Surong, and the smaller one is 0.47μF 450V.

Another larger capacitor is 1μF 450V.

Those two GaN transistors are connected in parallel and used for the PFC boost. Model is GaN Systems GS-065-030-2-L. It adopts a PDFN8*8 package, and the resistance is 50mΩ. Withstand voltage is 650V, and the transient withstand voltage is 850V. It simplifies the gate drive requirements and has better reliability. The gate drive voltage is 0~6V, and the transient withstand voltage is -20~10V.

Datasheet of GaN Systems GS-065-030-2-L.

To shorten the product development period, GaN Systems also provides 65W QR chargers, 100W dual USB-C PD chargers, 140W PFC+QR, and 250W PFC+LLC fast charging solutions for customers.

Since the PFC controller is in the CCM mode, the PFC boost rectifier is a silicon carbide diode and can take advantage of no reverse recovery current. The silicon carbide diode is from HOEN CH3D10065E and adopts the TO252 package. Withstand voltage is 650V.

A diode and some magnetic components are soldered on the back of the small PCB. The PCB is designed by AcePower, which is the Sub-brand of Honor Electronic. It is committed to providing customized power supply design and manufacturing solutions for high-end tech brands.

The PFC boost inductor is placed in the hollow of the PCB to reduce the thickness. The magnetic core is wrapped with copper foil for shielding, marked with EQ3317.

The plastic case can insulate the high-voltage capacitor and low-voltage components.

Two electrolytic capacitors are from Suscon.

100μF 450V.

The primary controller is from NXP TEA2017AAT, which is a digital configurable LLC and PFC combo controller for high-efficiency resonant power supplies. It can act as LLC and PFC controller. It also integrates high-voltage startup, X-capacitor discharge and driver, which can simplify the circuit.

Those two LLC MOSFETs are from Oriental Semi OSS60R190JF. Withstand voltage is 650V, and the resistance is 190mΩ. They have outstanding low on-resistance and lower gate charge, which can reduce loss and improve performance.

Those two power supply capacitors for the primary controller are 330μF 25V and 220μF 25V, respectively.

The LLC resonant capacitor is from Surong.

0.047μF 630V.

The magnetic core of the resonant inductor is marked with EQ19.

The magnetic core of the transformer is marked with EQ3313. And the low-voltage side is tightly wound with tape for insulation.

Two EL1013 optocouplers are used for output voltage feedback and protection, respectively.

The blue Y capacitor is from STE.

Here is the synchronous rectification circuit, which consists of two synchronous rectifier MOSFETs and a synchronous rectifier controller.

The secondary synchronous rectifier controller is from NXP TEA2095T. It integrates two drivers, which can drive two synchronous rectifier MOSFETs at the same time. It also supports the power supply voltage of 4.5-38V and synchronous rectifiers driven by logic voltage. The maximum operating frequency can reach 1MHz.

The synchronous rectifier is from Infineon, model is BSC028N06NS. It is an NMOS and adopts the SuperSO8 package. Withstand voltage is 60V, and the resistance is 2.8mΩ.

Here is the output end of the power adapter. We can see some solid capacitors, output wires, and an indicator light.

Those five output filter capacitors are the same. All of them are from PolyCap, used for output filtering.

470μF 25V.

Here is the dual operational amplifier, used to control the constant voltage and current of the secondary side. Model is DIODES AP4310E. It can work with sampling resistor to detect the output current.

The R002 sampling resistor is used for output current acquisition and adopts 2512 package.

The output wires are soldered on PCB and are insulated by heat-shrinkable tubes.

Here is the output power indicator.

Ok. That’s all components of this Razer 280W GaN charger.

Summary of ChargerLAB

This Razer 280W power adapter is significantly smaller than traditional power adapter, reflecting the performance improvement brought by GaN components. You can even replace another detachable braided cable when broken, making it more durable. With the indicator light, you can easily get the working status.

The PCBA module is wrapped with cure copper for heat dissipation. And the internal components are covered with silicone adhesives for heat dissipation.

We found it adopts the PFC and LLC architecture, which is customized by Honor Electronic. And the primary controller from NXP TEA2017AAT can act as LLC and PFC controller. Two GaN transistors for PFC boost are from GaN Systems (GS-065-030-2-L) and connected in parallel.

The synchronous rectification circuit consists of NXP controller and two Infineon MOSFETs.And then, the output current is filtered by PolyCap capacitors.

Because of the GaN components inside, this adapter has a compact size, bringing consumers a portable high-power power supply.

Related Articles:

1. (Video) Teardown of Razer Blade 280W GaN Power Adapter (RC30-042)

2. (Video) Latest Teardown of Brand New Apple 140W USB-C GaN Charger

3. Up to 240W | Teardown of Alienware 240W GaN Charger (For m15 RYZEN EDITION R5 Laptop)