Introduction

The fact that the iPhone 15 series features USB-C ports is definitely good news in the long run. But it may not be so for long-time Apple users who have many Lightning cables. To prevent users from wasting resources, Apple has introduced the USB-C to Lightning Adapter.

ChargerLAB got this adapter immediately. And next, we will take a look at its build quality compared to similar products we have previously took apart, such as the USB-C to Apple Pencil Adapter.

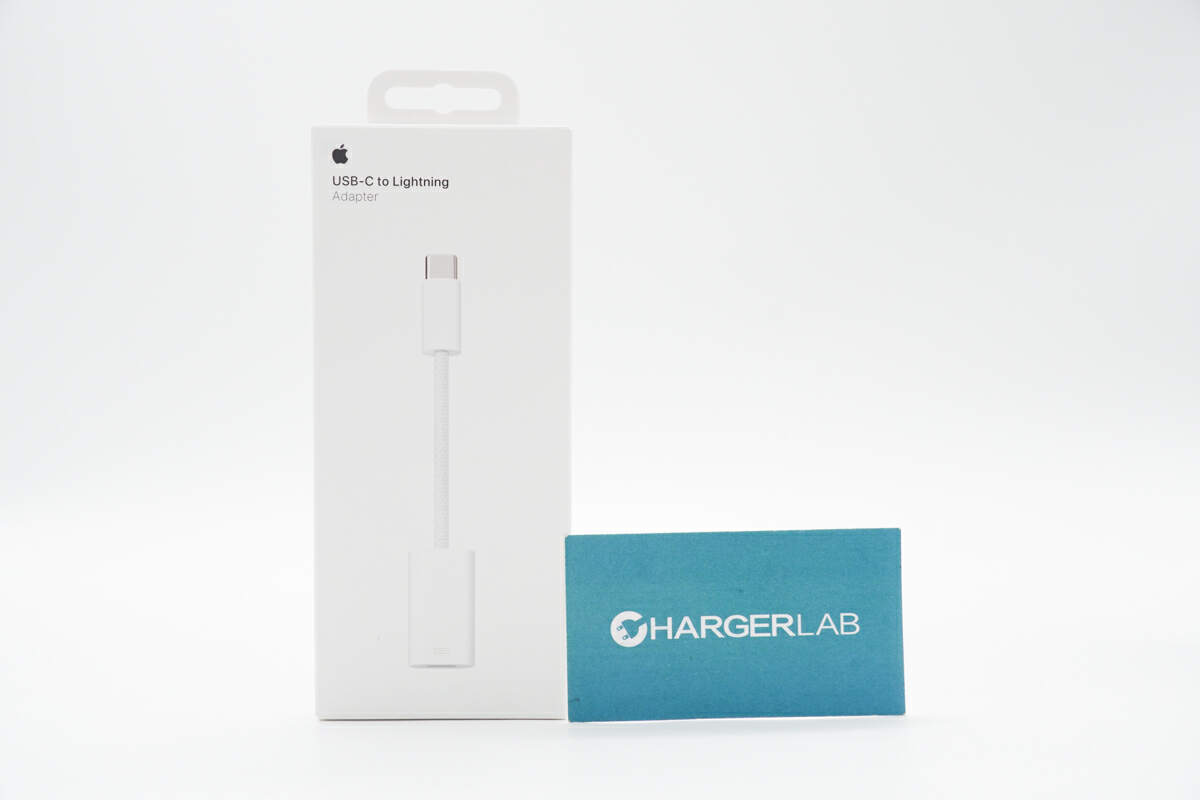

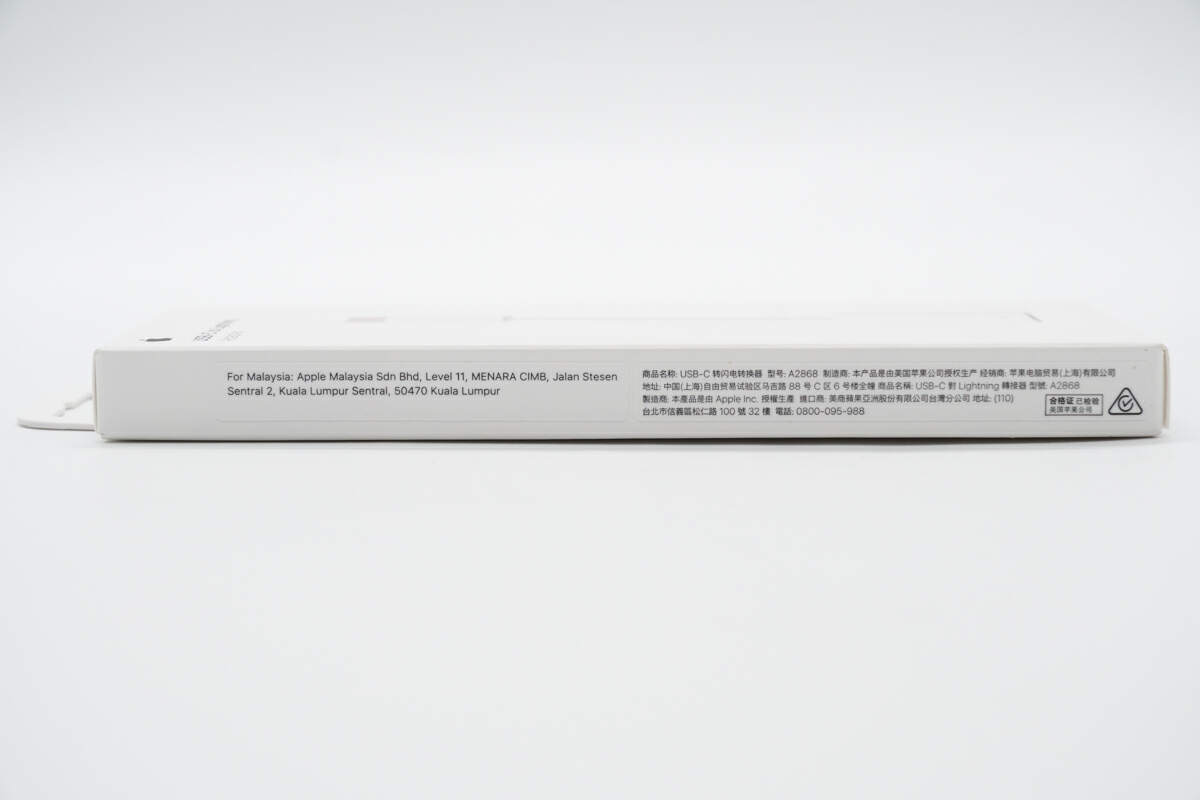

Product Appearance

As usual, the packaging box adopts the Apple style.

It shows you how to use the product on the back.

The model is A2868.

This adapter is compatible with iPhone and iPad models that come with USB-C port.

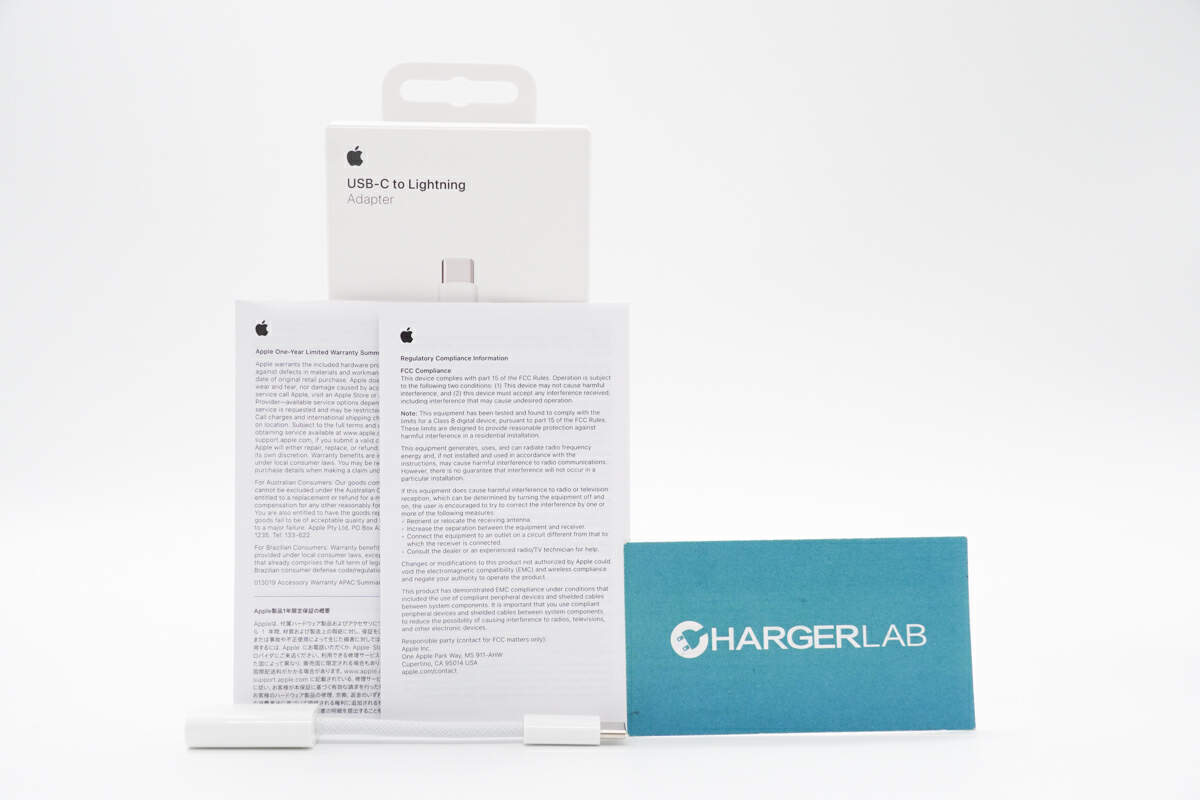

The box contains the adapter itself and some documents.

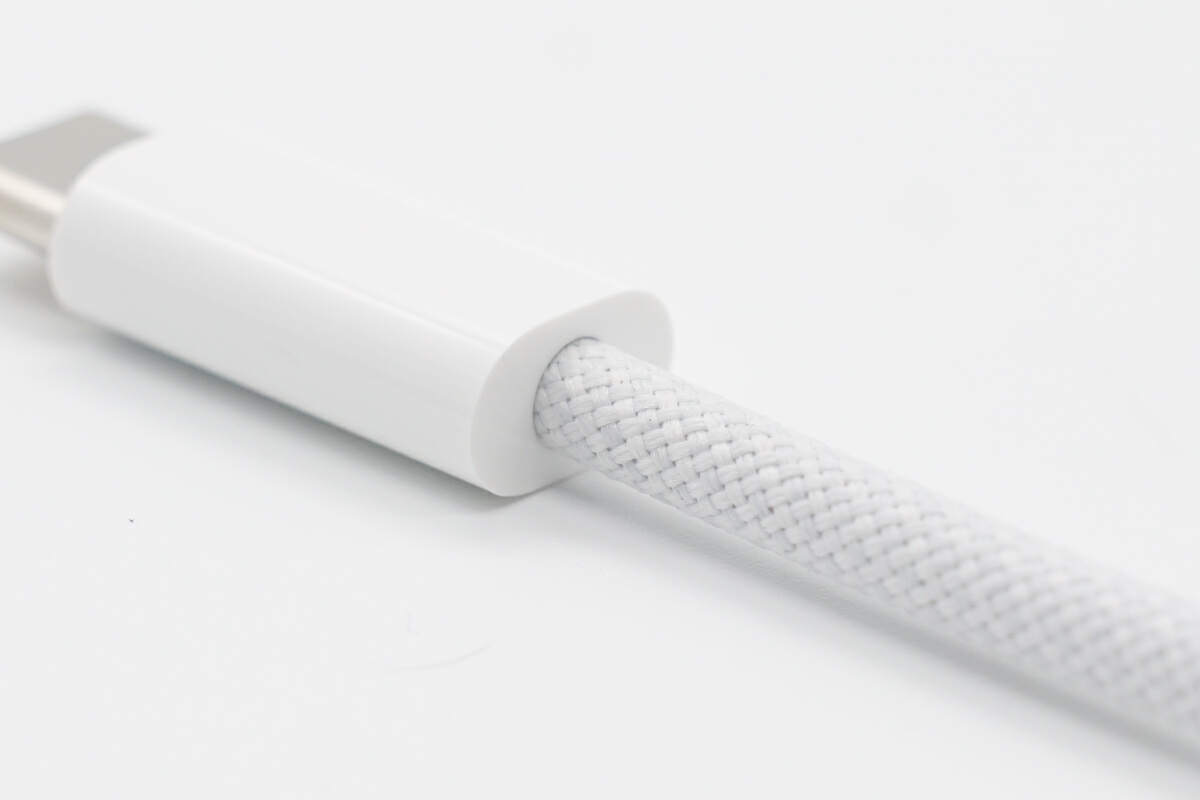

The cable part is also in a woven design, just like the included USB-C cable for the iPhone 15 series.

The USB-C connector adopts a non-full-pin design, and the pins are gold-plated.

There is no protective sleeve between the connector and the cable.

And there's a Lightning icon on the other side.

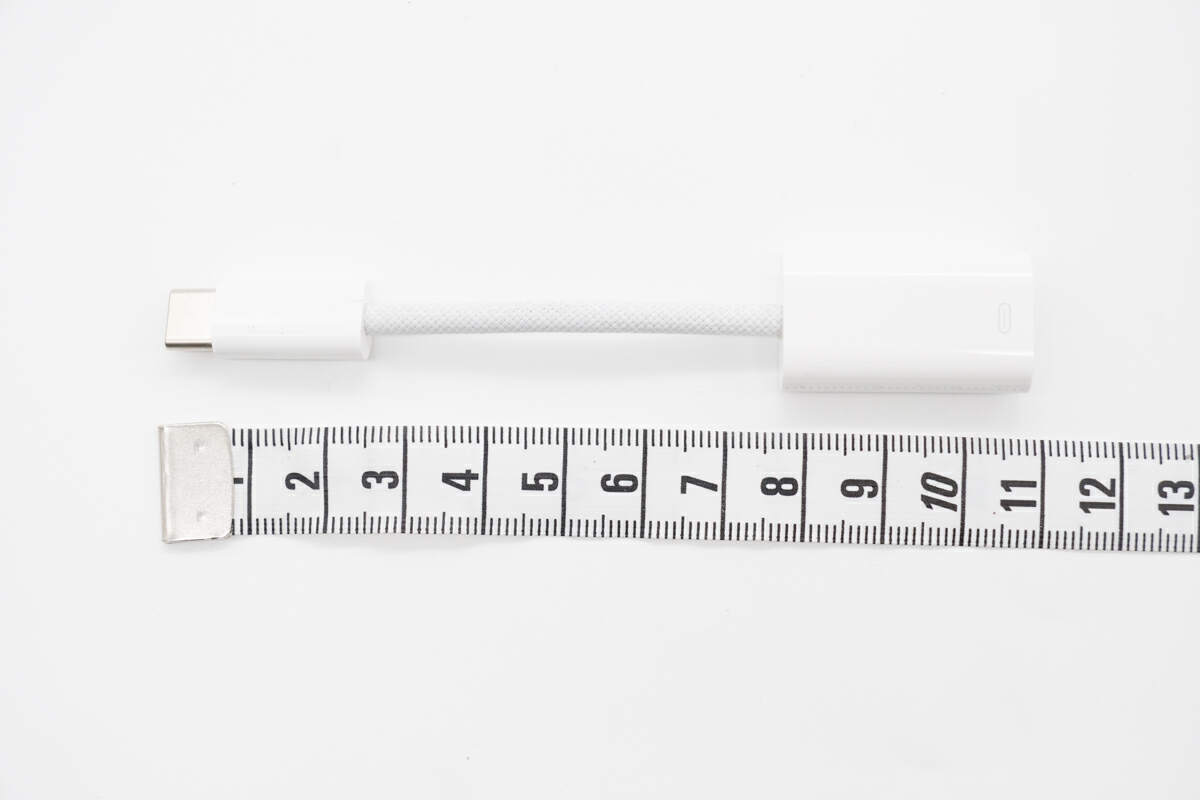

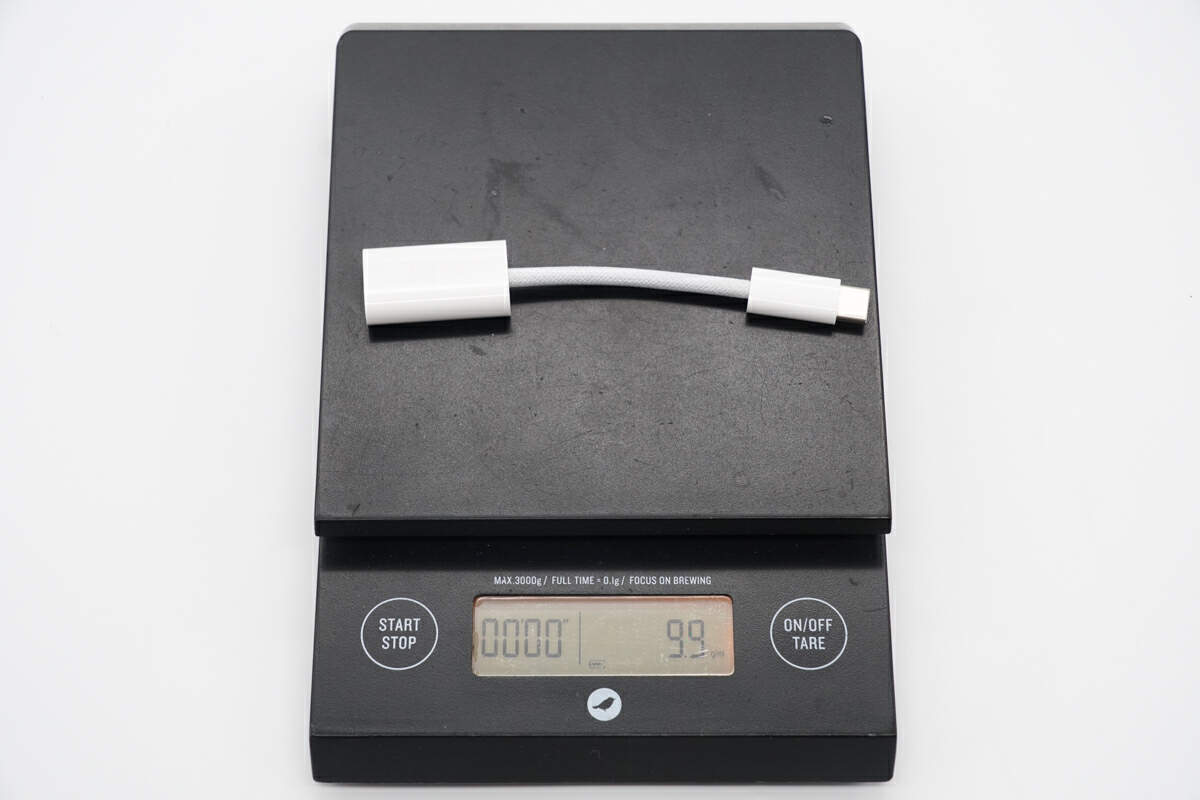

The length is only about 11cm (4.33 inches), which makes perfect sense for an adapter.

And the diameter is about 3.6mm (0.14 inches).

This is how it looks like on my hand, pretty tiny.

The weight is about 10g (0.35 oz).

The ChargerLAB POWER-Z KM003C shows it doesn't have E-marker chip, obviously.

This product arrived before the iPhone 15 series, so we can only perform a simple test on the iPad Pro. The charging power can reach up to 25.75W.

Teardown

Next, let's begin the actual teardown.

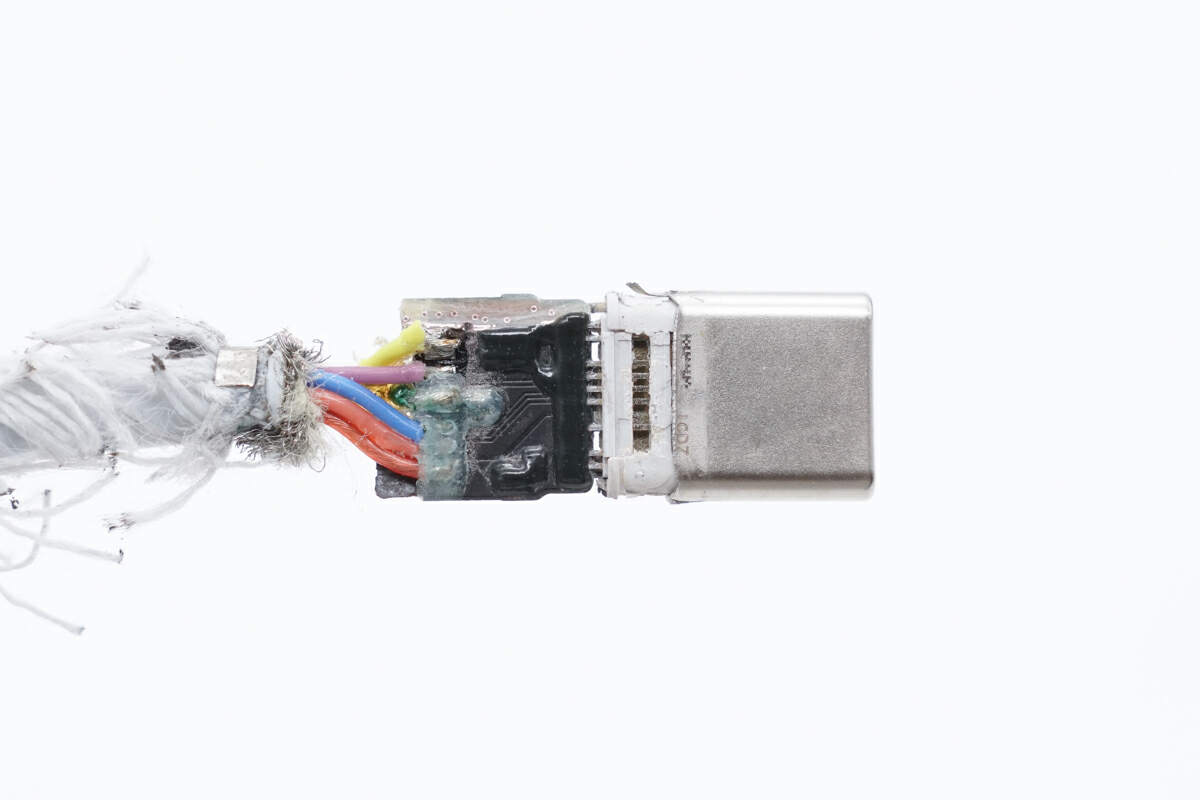

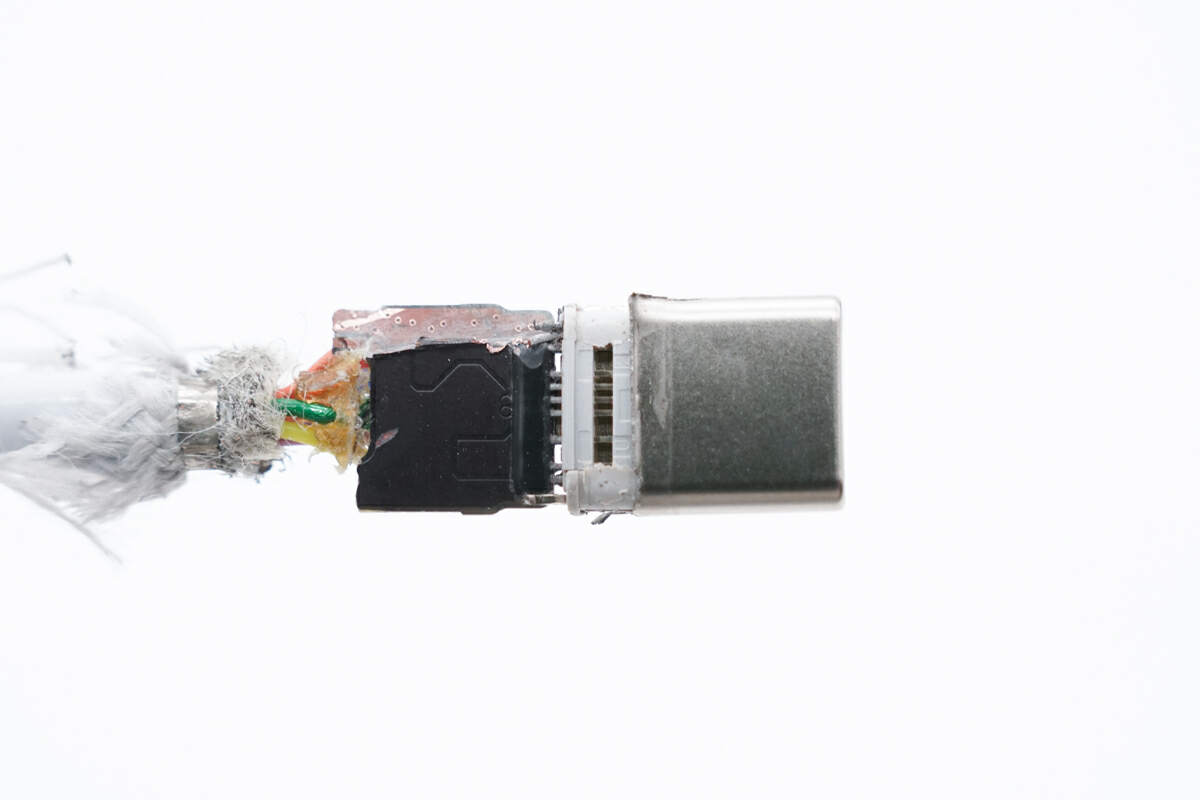

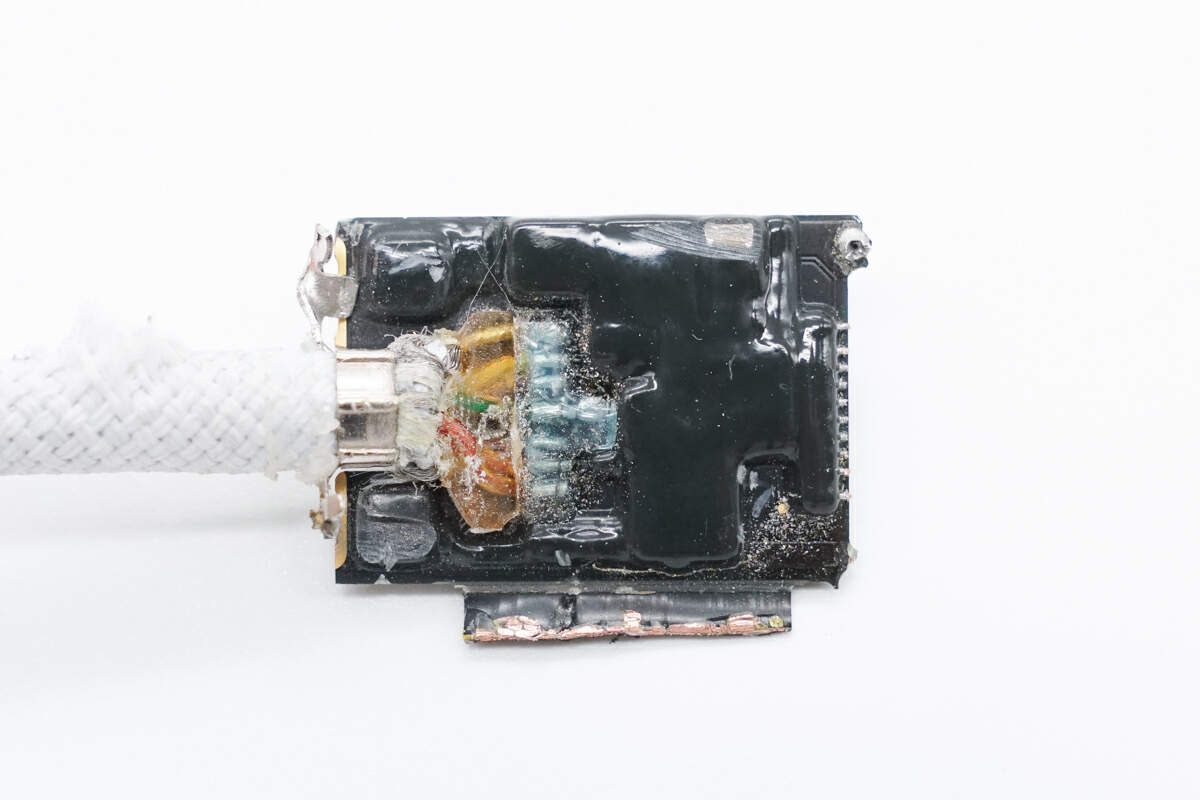

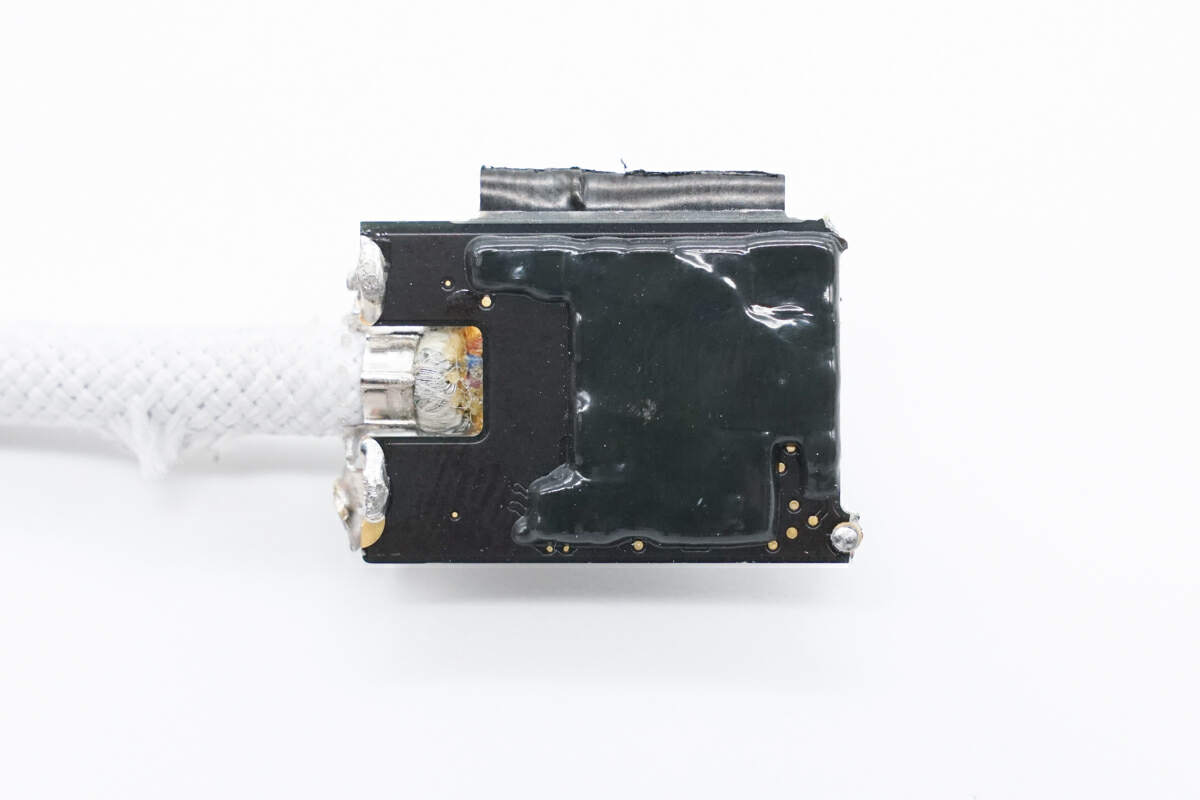

Firstly, use the cutting machine to cut off the USB-C connector. Just the Apple 240W USB-C Charge Cable we just took apart before, it has a steel sleeve to protect internal components, which is fixed by plenty of solder joints.

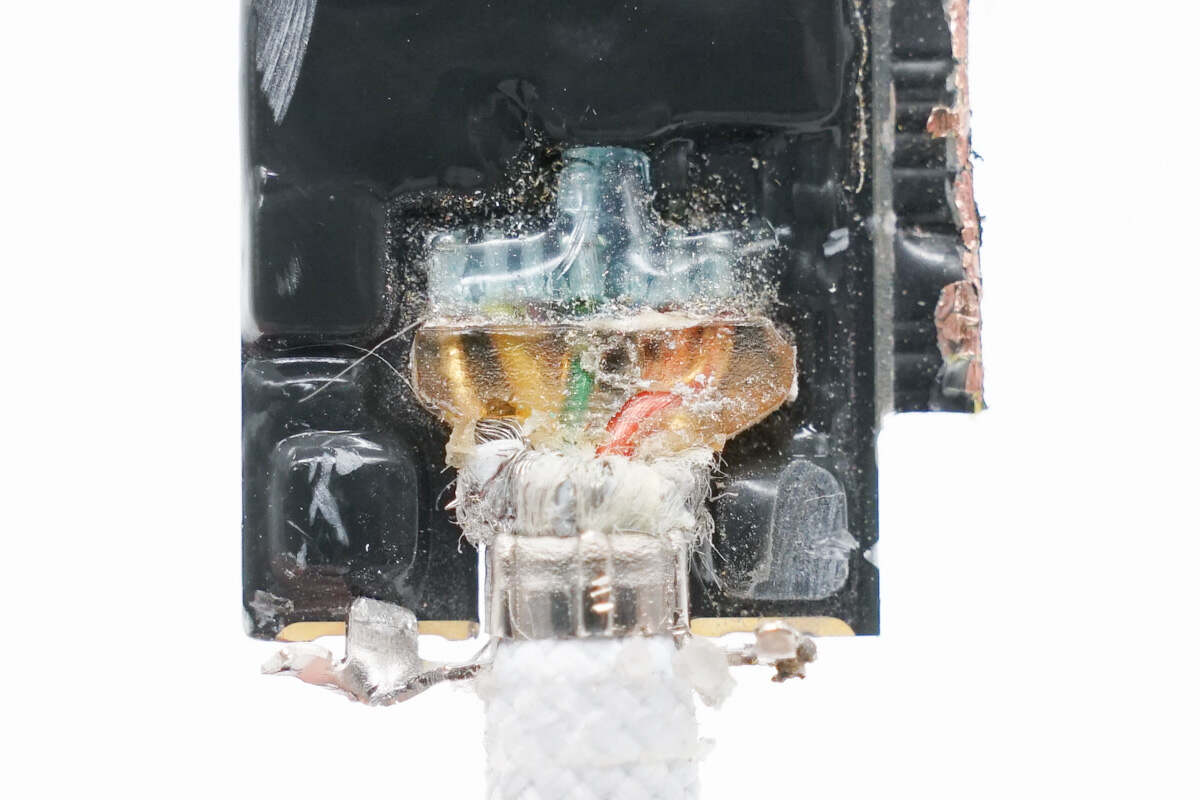

Continuing to remove the steel sleeve, you can see a lot of potting compound on top of the black PCB.

All the wires are connected to this side, all of which are reinforced with glue.

And there are no components on the back.

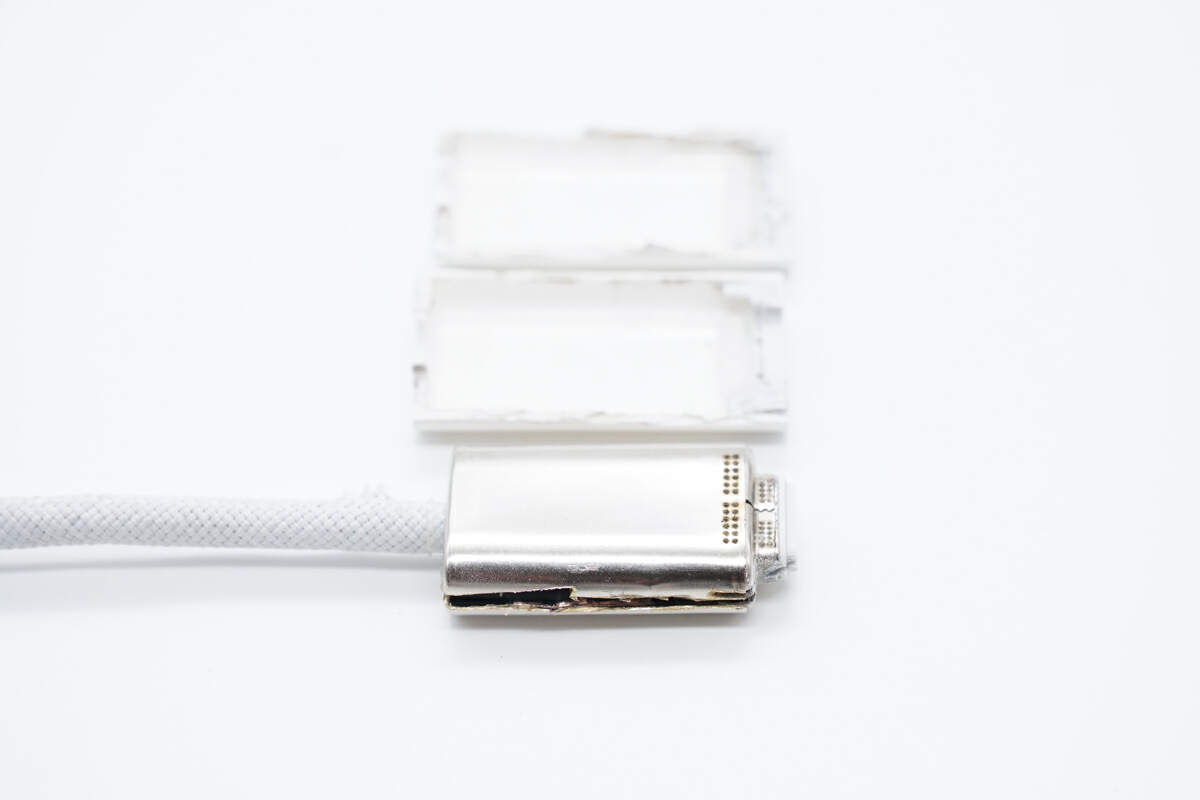

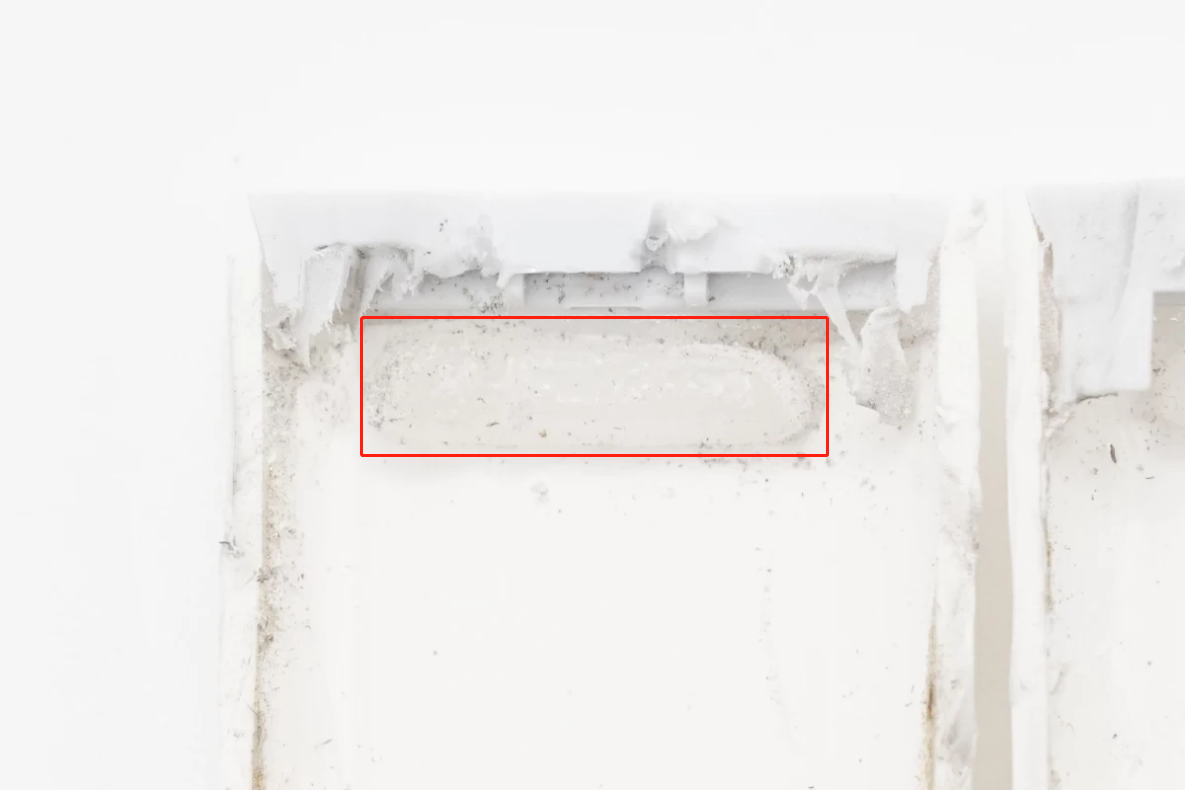

Moving on to the Lightning part, it also has a steel sleeve to protect internal components.

There is soft rubber on the shell for fixing.

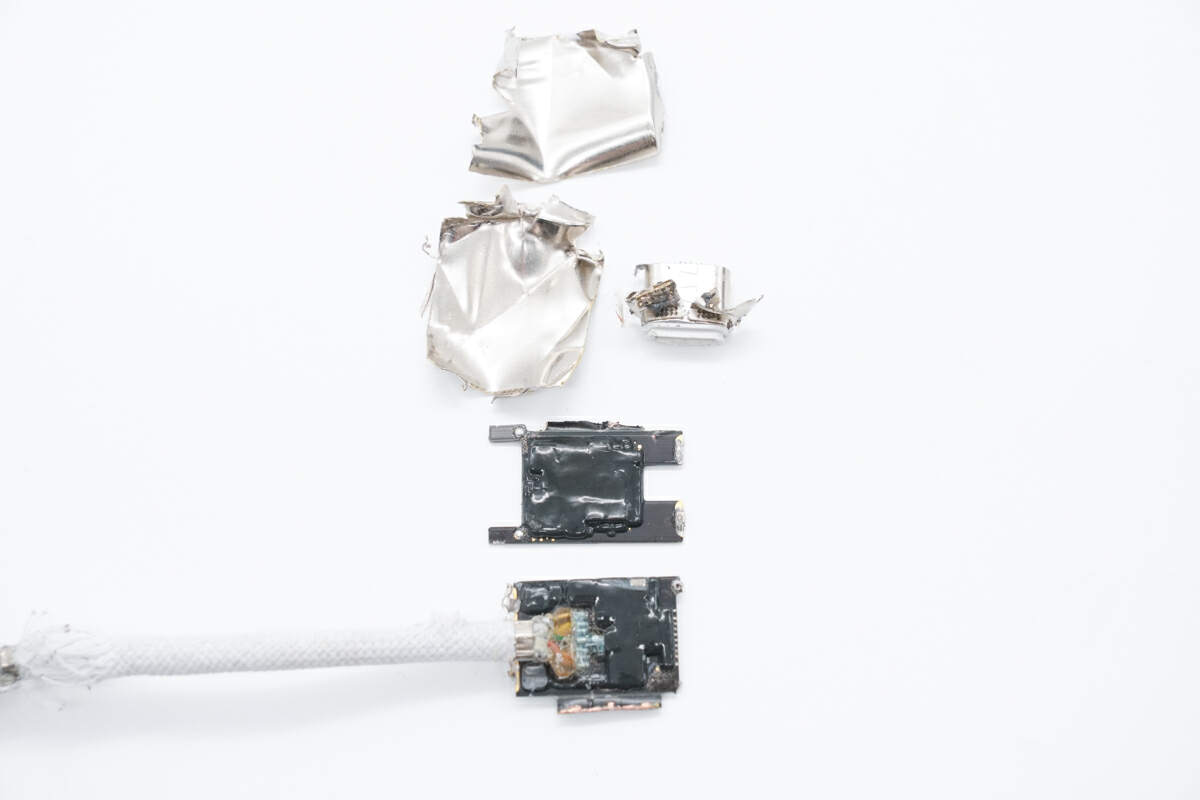

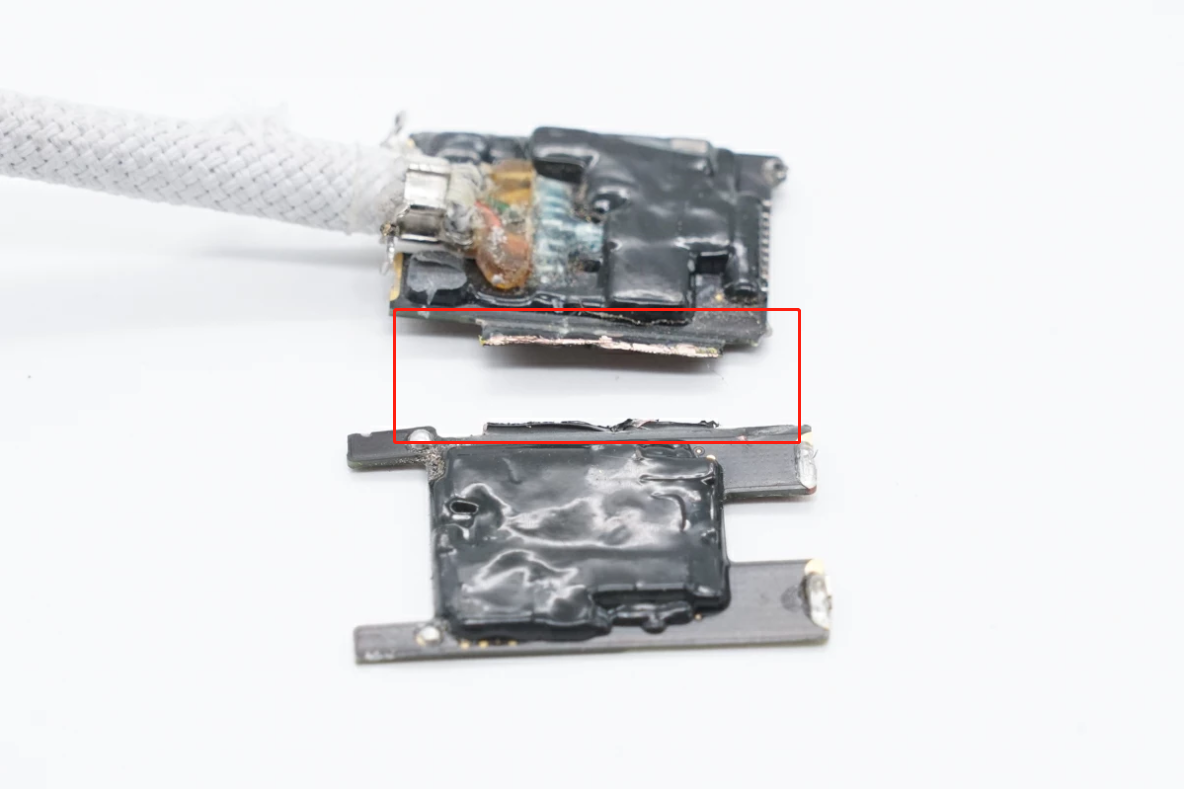

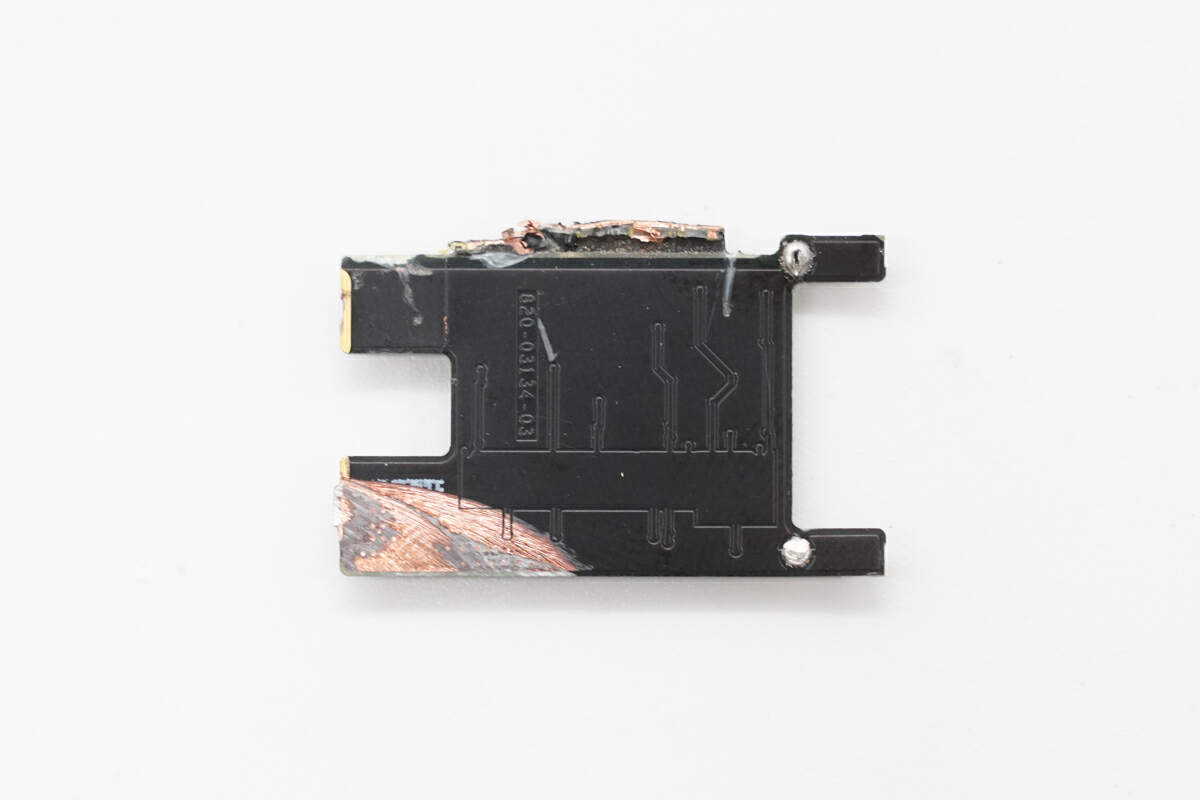

Continuing to remove the steel sleeve, there are two PCBs inside.

They were originally connected through the extension parts within the red frame.

The first PCB is covered with a lot of potting compound.

The solder joints of the wires are reinforced with glue.

The back only has potting compound.

The other PCB also has potting compound applied in the same way.

And there is nothing on the back.

Next is the cable, you can see red, yellow, blue and green wires.

There's a layer of white TPE, followed by the shielding net.

No aluminum foil.

Here is a close-up of the cable's internal structure, including the outer woven layer, white TPE, shielding net, and data wires.

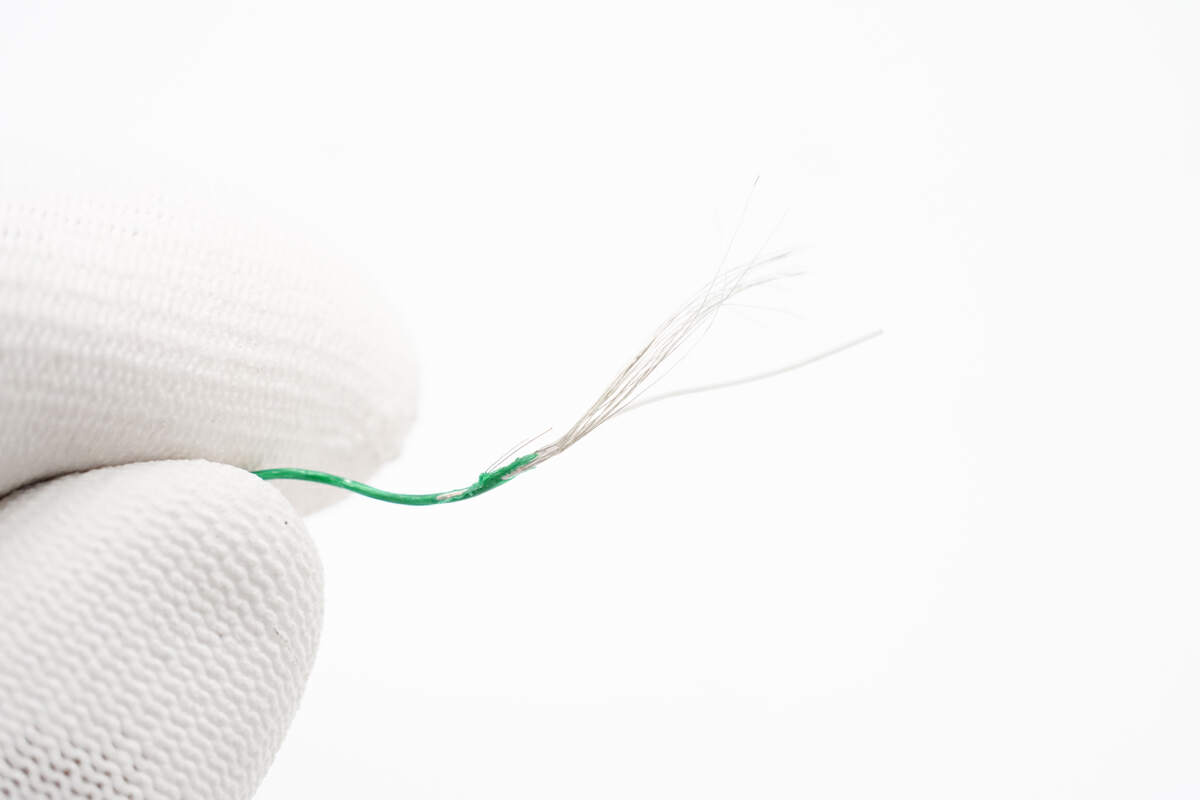

These two positive power supply wires are made of tinned copper.

Here is the green wire.

Purple wire.

Yellow wire.

Blue wire.

These five bare tinned copper wires are used for negative power supply.

Well, that would be all the components of the two connectors and the cable.

Summary of ChargerLAB

In terms of build quality, the extensive use of potting compound inside and the special way of connecting the two PCBs are top-tier. And these advantages somehow justify the $29 price tag.

If you already have plenty of Lightning cables on hand, it is recommended to purchase this adapter to help protect the environment. If not, you may consider buying a brand new USB-C to USB-C cable instead.

Related Articles:

1. Teardown of USB-C to Apple Pencil Adapter (For iPad 10th Gen)

2. Teardown of Apple USB-C to SD Card Reader (For Mac and iPad)

3. Teardown of Apple USB-C to Lightning Adapter (Video)