Introduction

Over a year ago, we took apart the 1.8m and 3m versions of the Apple Thunderbolt 4 Pro cable, both undeniably among the best-built cables. This time, we got ourselves the latest and most affordable one in this series - the 1m version. So, are there any differences in build quality? Let's find out.

Product Appearance

The packaging box continues Apple's classic design.

And the product name, some icons are on the back.

The sticker on the side shows it's compatible with USB-C Thunderbolt 3 devices.

As usual, it's fixed by cardboard.

Just like the other two cables, it's pretty thick and adopts black braided design.

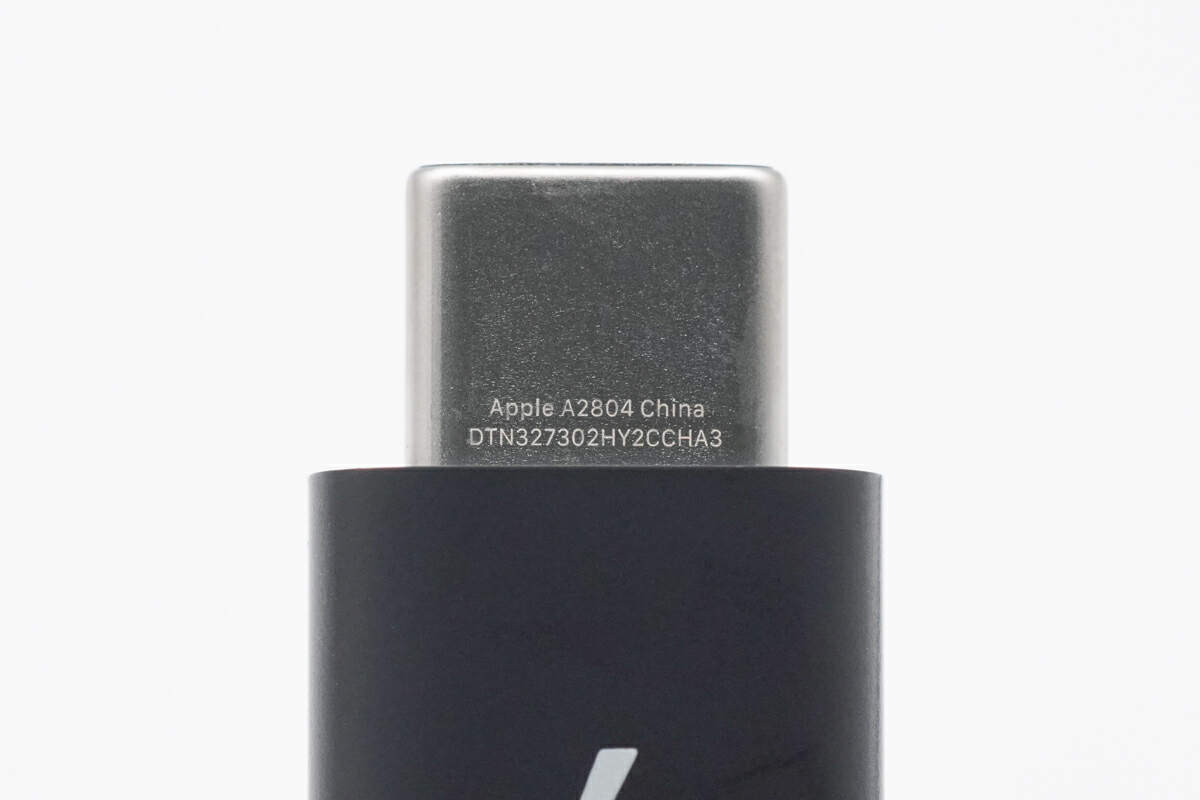

The connector is made of metal, which is rare. And it's actually shorter than the other two version.

And it's made in China. Model is A2804.

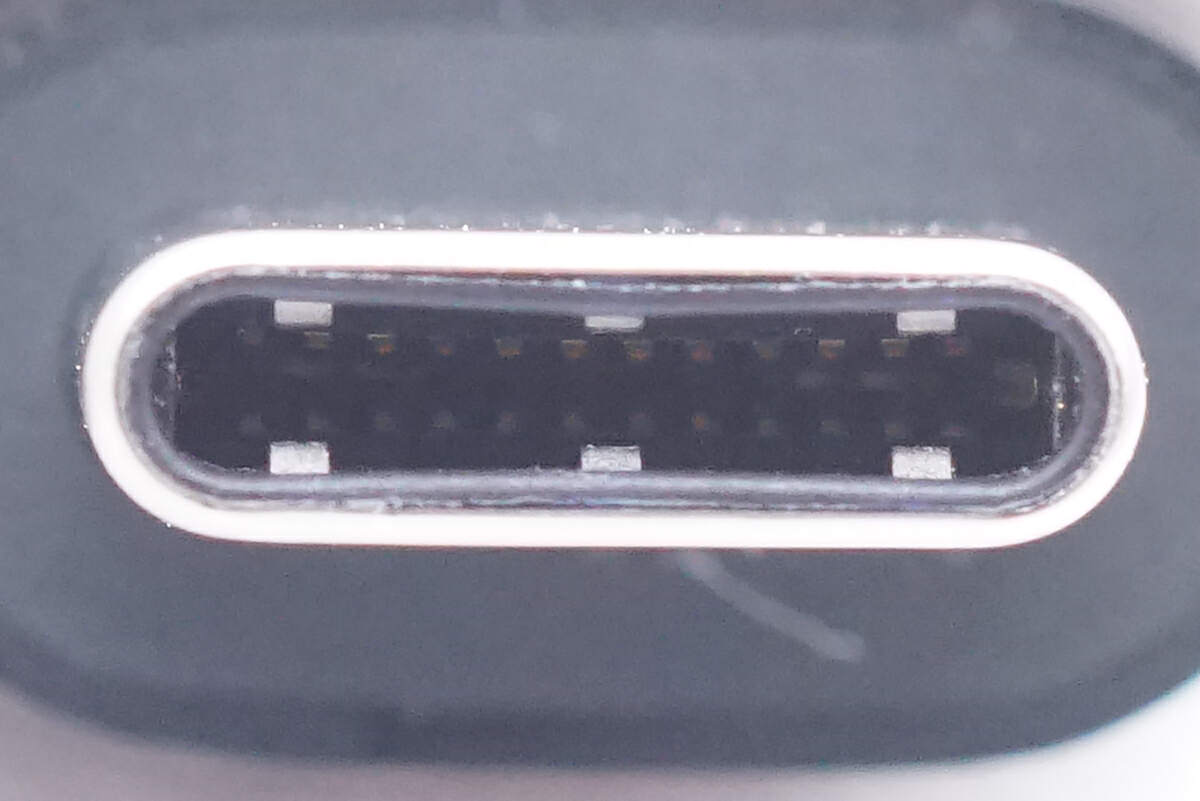

It adopts a full-pin design.

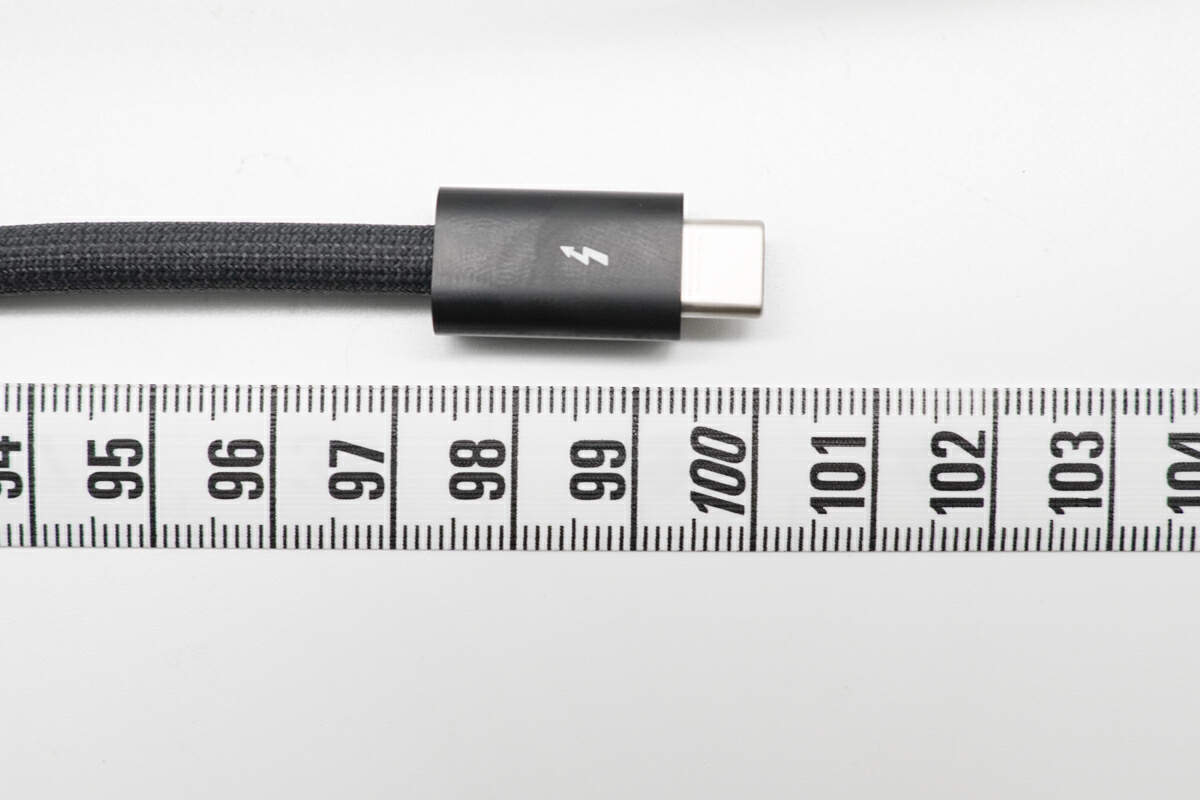

The cable length is exactly 1m (3' 3.36'').

The diameter is 4.78mm (0.19 inches), which is relatively thicker compared to standard cables. But it's actually slightly slimmer when compared to the previous two versions.

And the weight is 56g (1.98 oz).

This is how it looks like on my hand, quite thick.

The ChargerLAB POWER-Z KM003C shows it's a USB4 Gen2 (20Gbps) cable that can support 20V5A 100W, and the data transfer speed can be up to 40Gbps.

Test

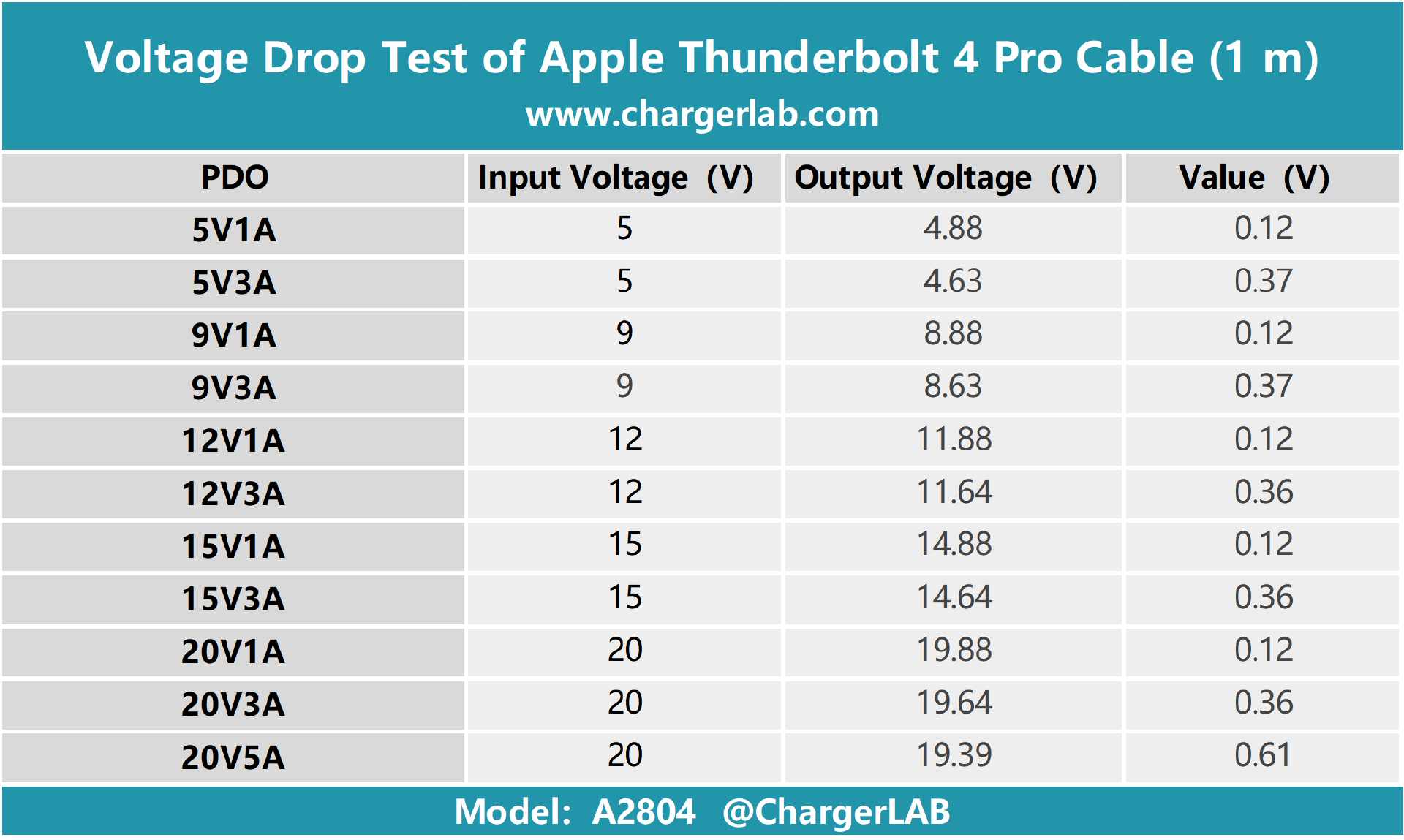

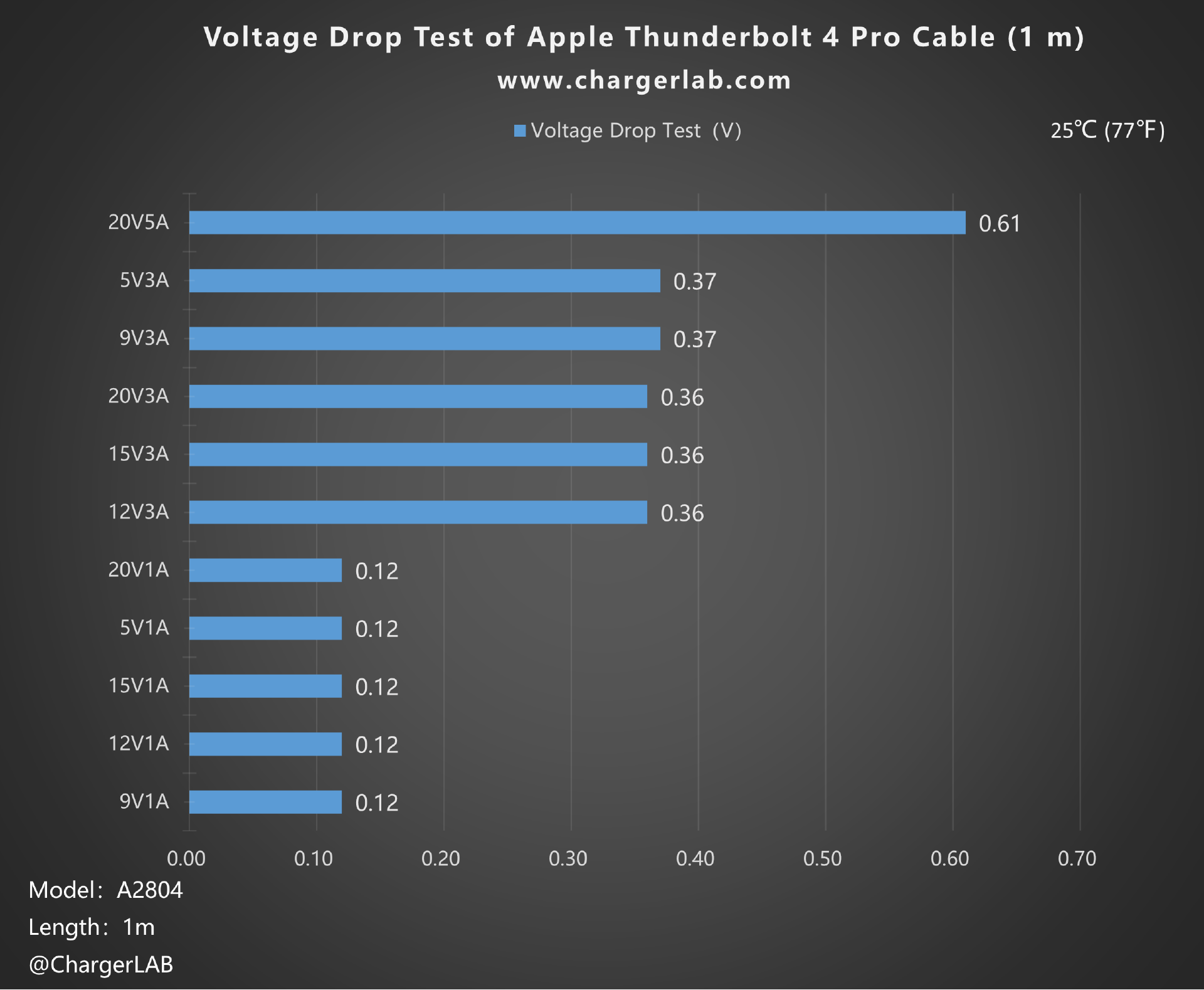

Before the teardown, let's do some simple test, starting with the voltage drop test.

This test measured the difference between the input and output voltages. And this spec is an important factor in measuring the quality of the cable.

From the chart, we can see that the voltage drop falls into three categories: 0.12, 0.36 and 0.61, with results similar to that of the Apple 240W USB-C charging cable.

Use it to charge the 13-inch MacBook Pro M2. The power is about 92W, so it does supports 100W.

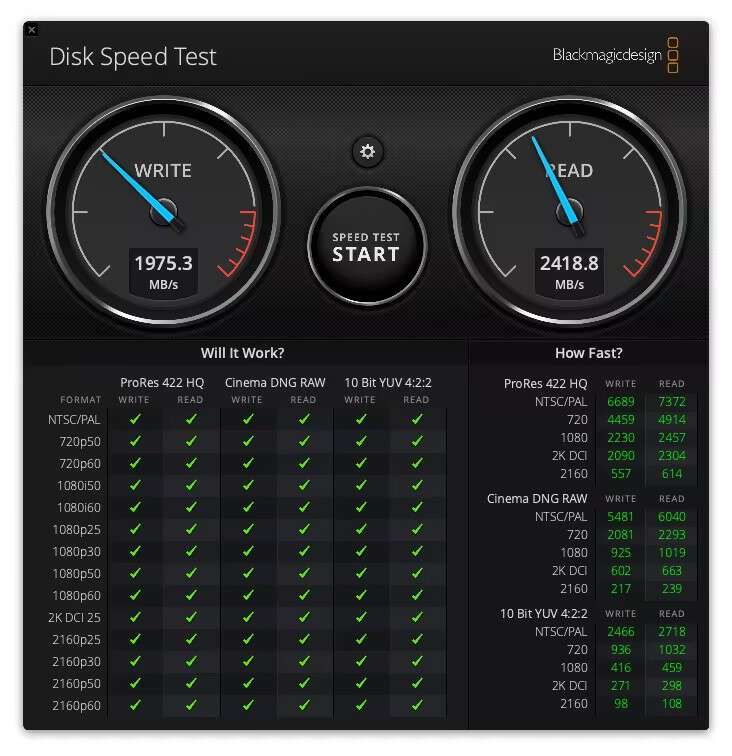

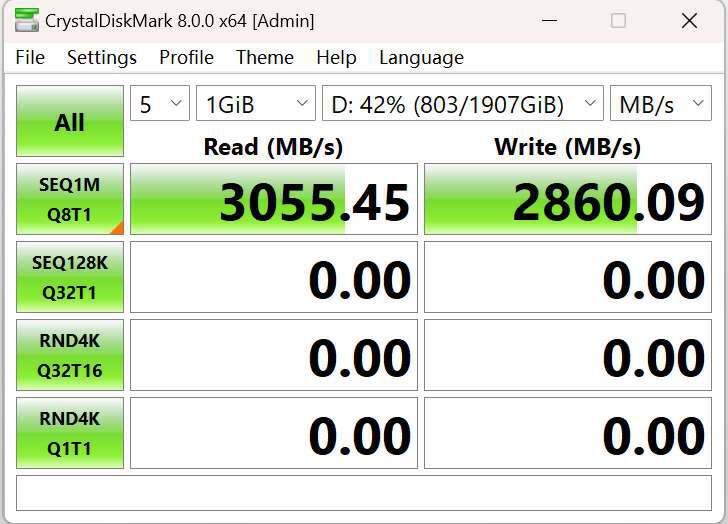

When it comes to data transfer speed, its read and write speeds can reach 2418.8 and 1975.3MB/s in macOS's Disk Speed Test, respectively.

In Windows, it has been boosted to 3055.45 and 2860.09MB/s, respectively. So, this cable is suitable for both Windows and macOS users.

Teardown

After simply reviewing this cable, let's take a closer look at its internal wires, components and build quality.

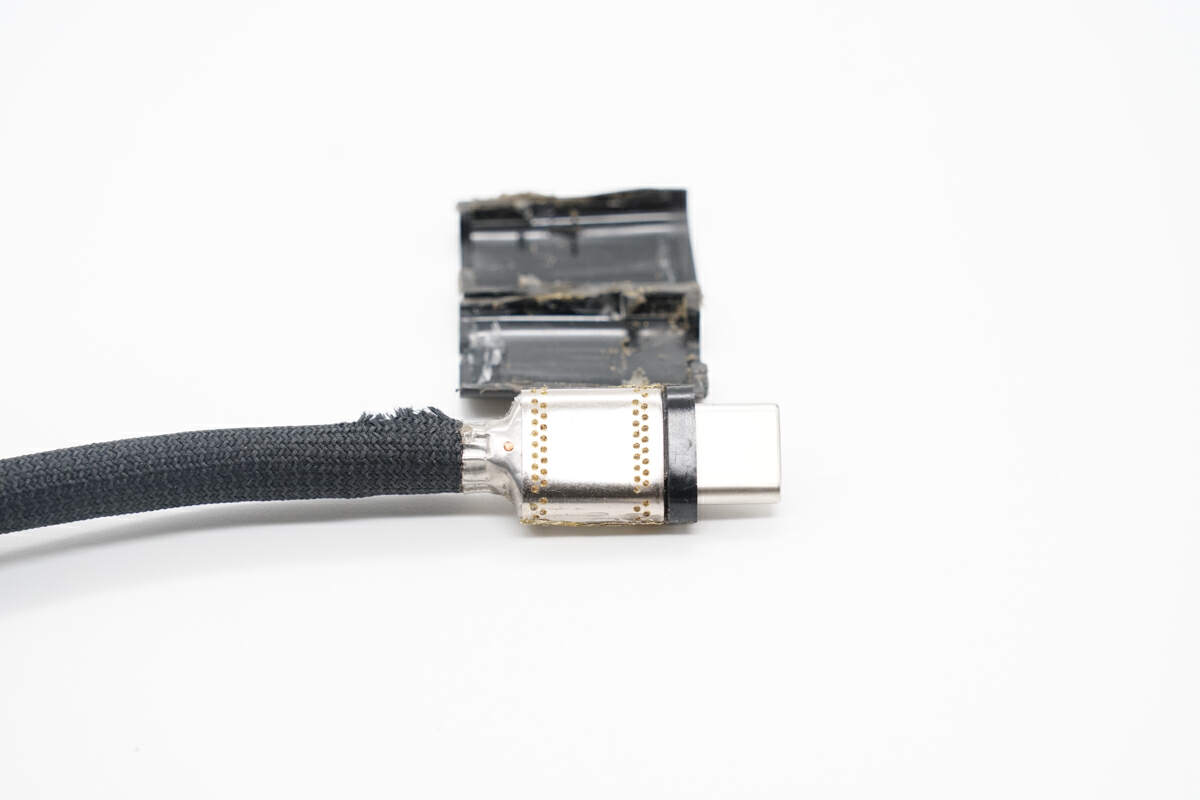

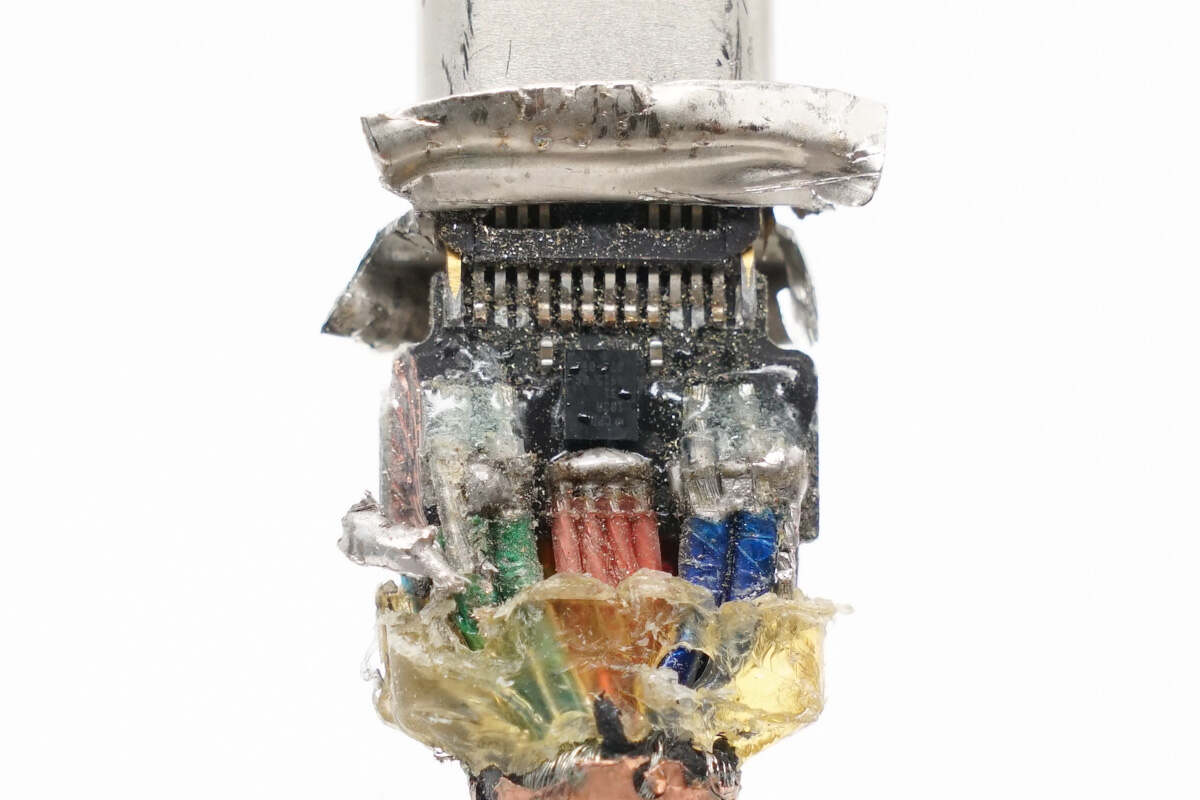

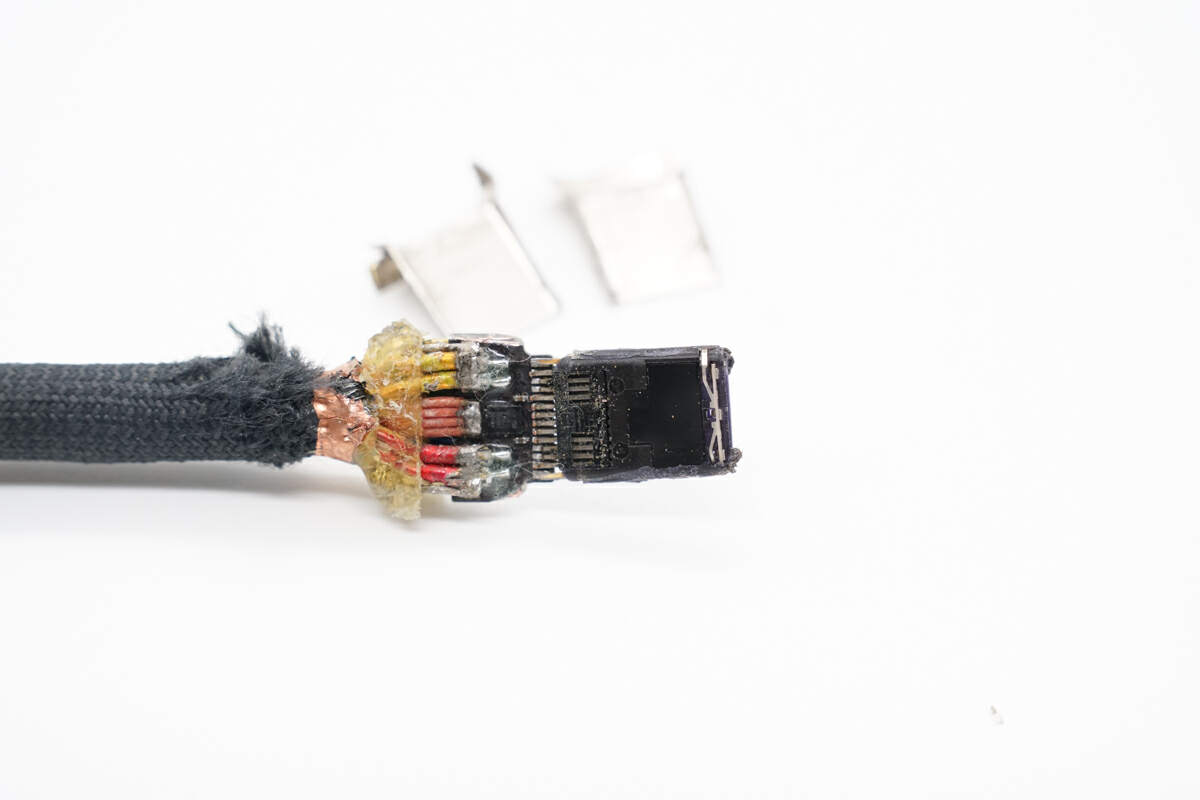

Firstly, using the cutting machine to cut off the USB-C connector. Just like all Apple cables in our previous teardown articles, it has a steel sleeve to protect internal components, which is fixed by solder joints.

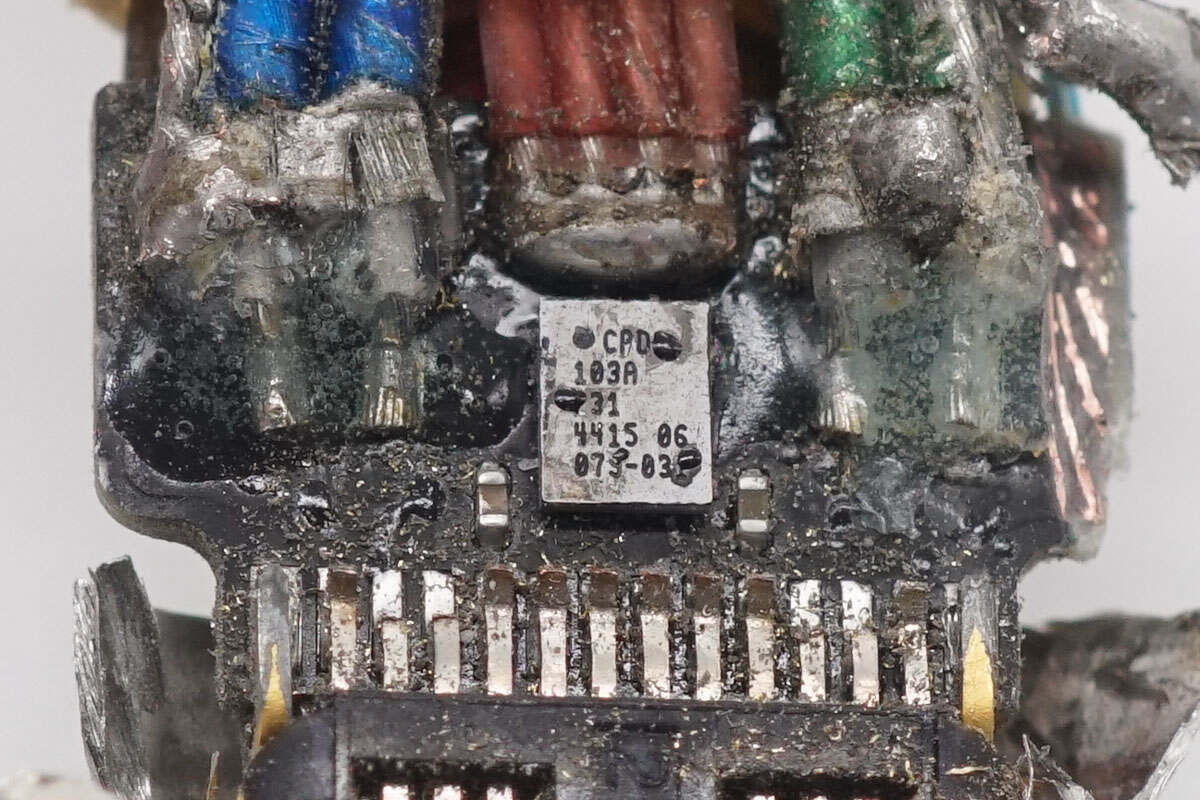

Continuing to remove the steel sleeve, then we can see the black PCB.

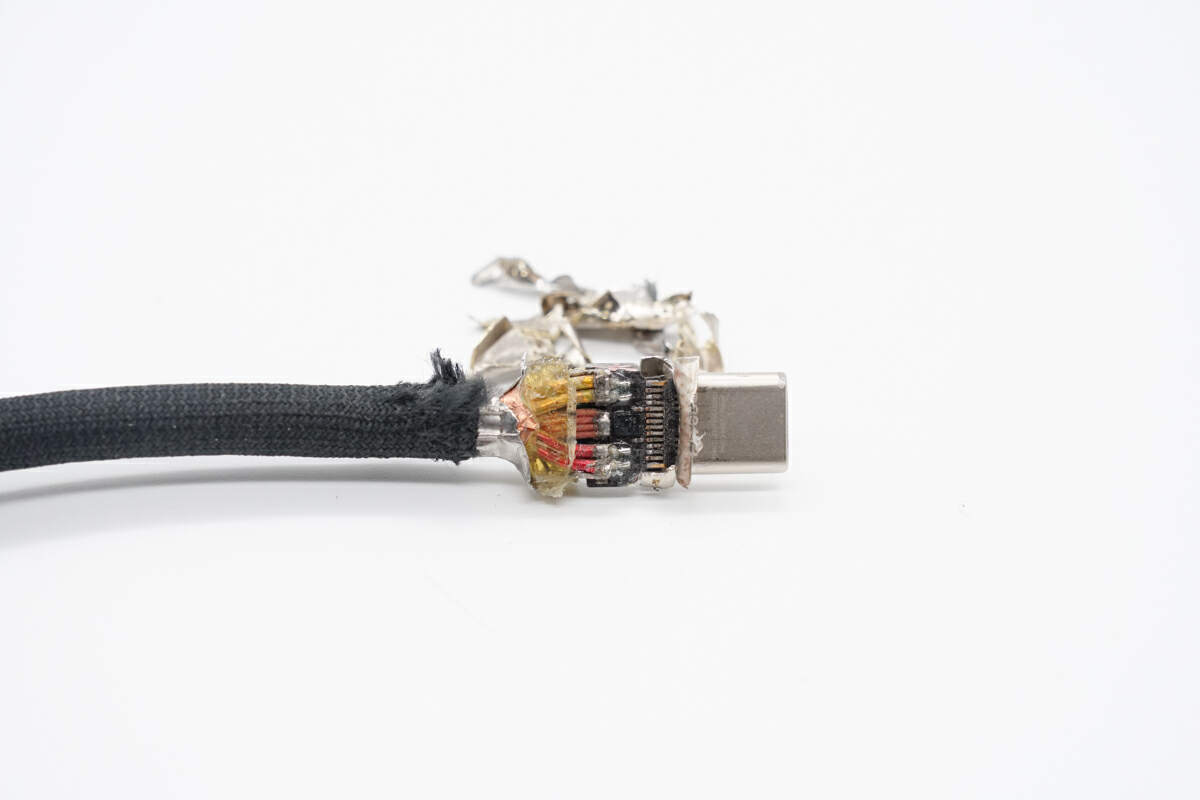

The coaxial wires are on both sides, the E-marker chip and four parallel positive wires for power supply are in the middle.

Coaxial and CC wires are on the back.

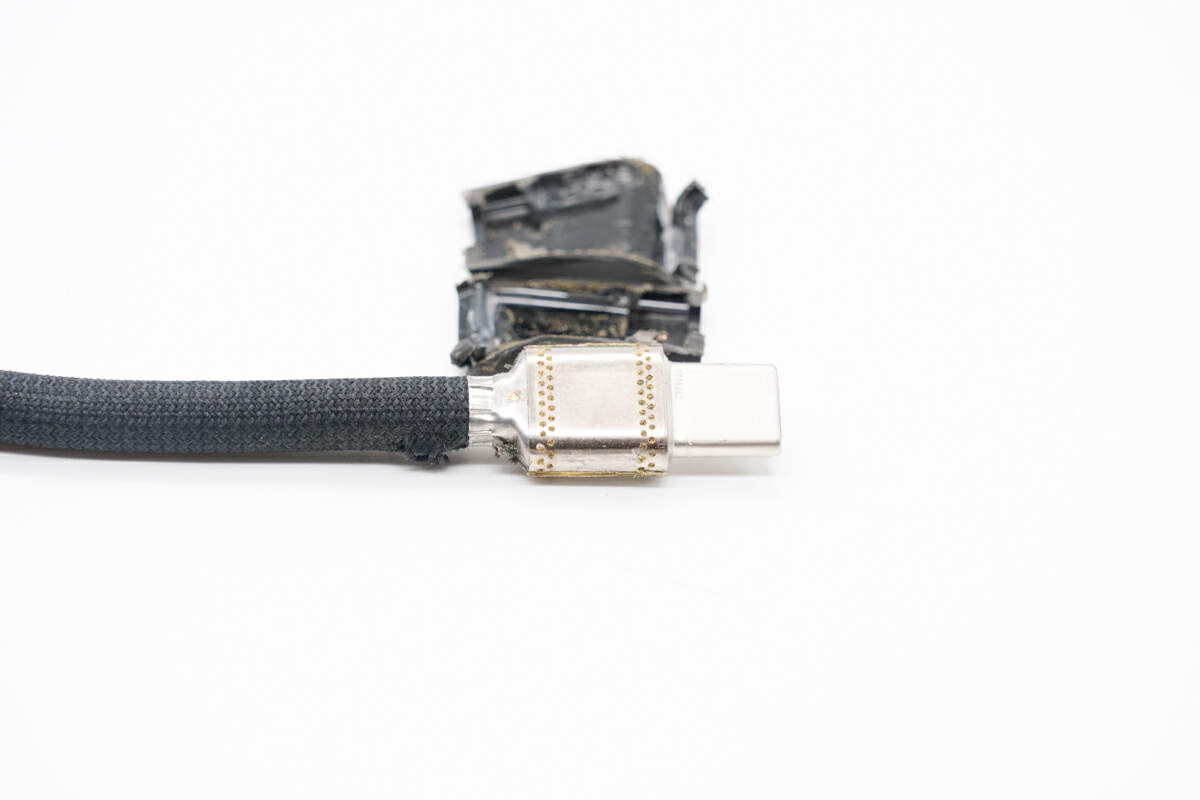

Then, let's take apart the other connector.

Both connectors are exactly the same.

All solder joints are insulated and reinforced with transparent glue. In fact, in terms of the number of chips and components, it falls far short of the 1.8m and 3m versions.

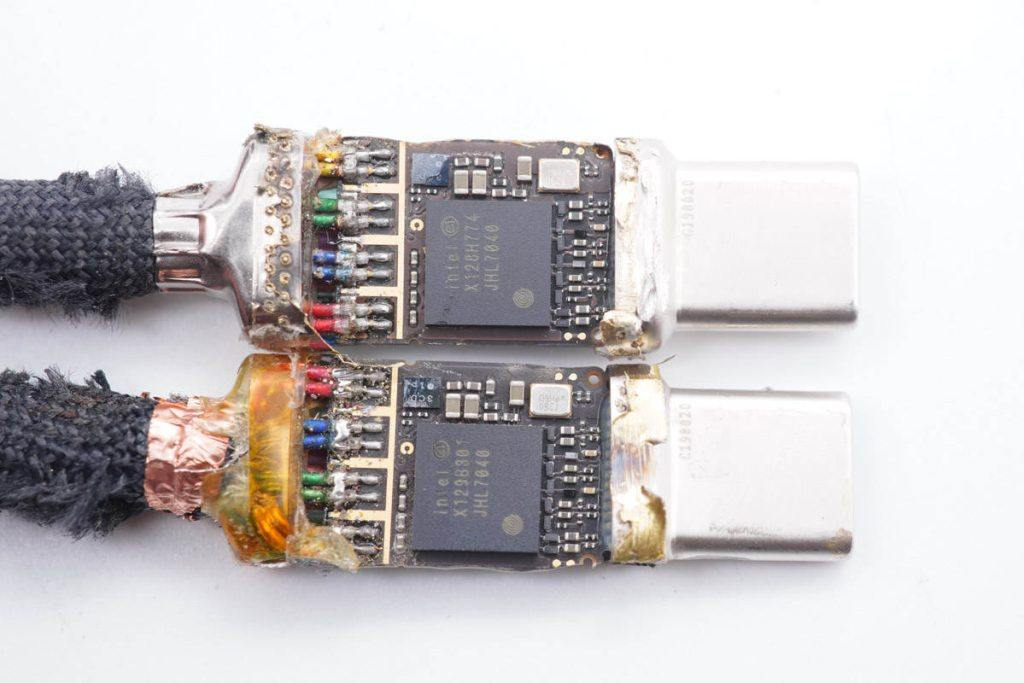

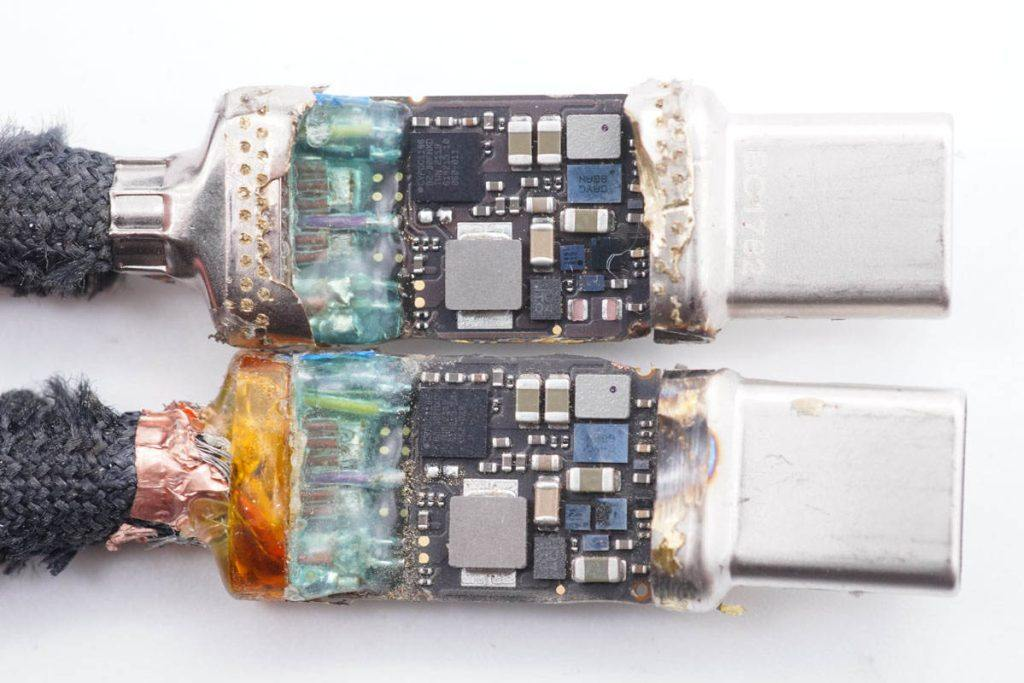

Taking the 1.8m version as an example, this is its front side. And the large chip in the middle is the Retimer.

The E-marker and other chips are on the back; however, this is quite reasonable, as we will discuss later.

The E-Marker chip is from Infineon, model CYPD2103A. It integrates a 48MHz Cortex-M0 processor, 32KB flash memory, and 4KB SRAM. It also supports working voltages from 2.7 to 5.5V and operating temperature range of -40 to 85℃.

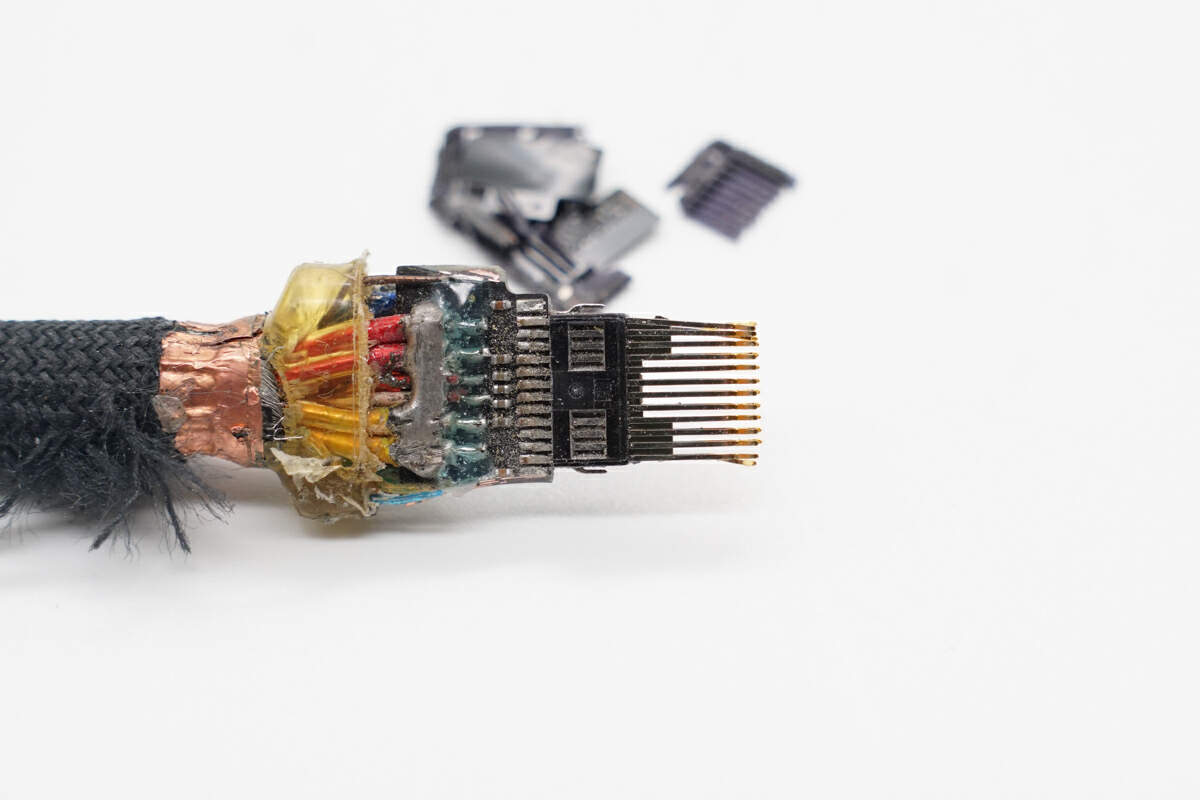

Next, we removed the metal shell of the USB-C connector. The pins are beneath the plastic frame.

Those pins are gold-plated.

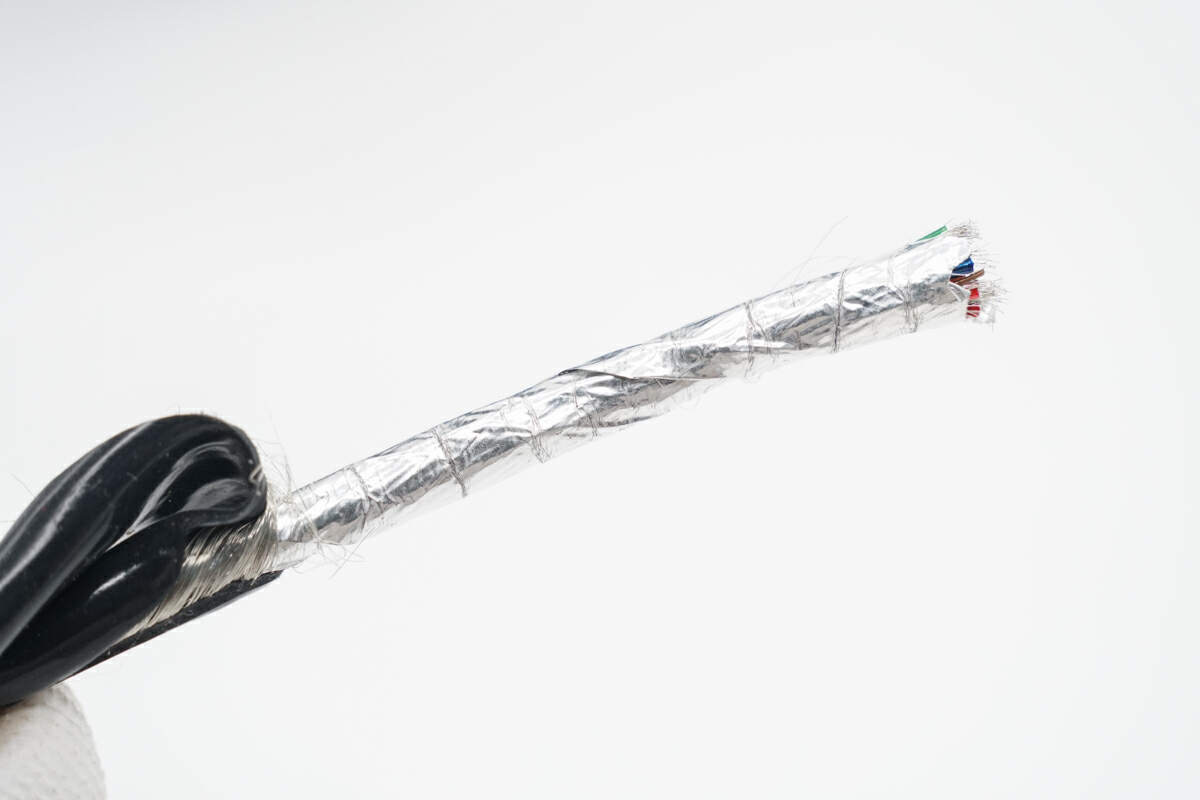

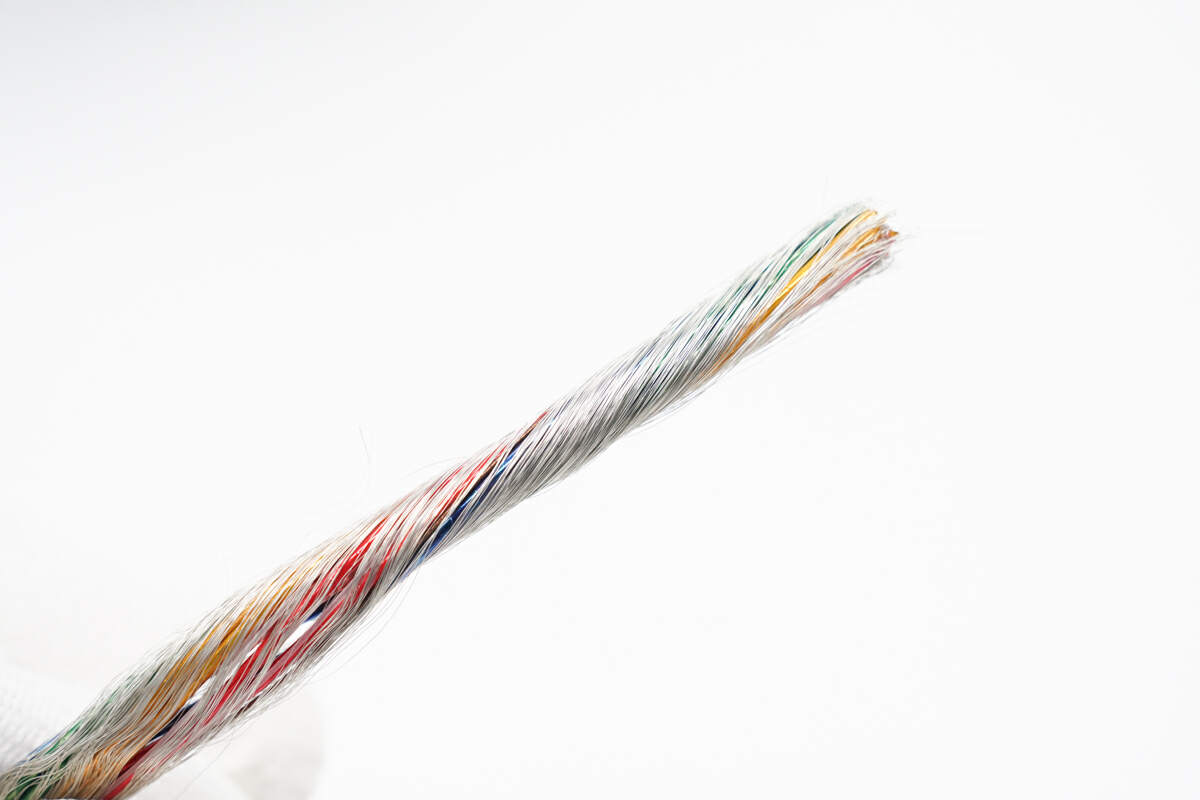

Next, let's cut off the cable. The twisted structure on the woven layer causes it to gather together even after being cut. The shielding net, coaxial wires, and the central positive wires for power supply, as well as the USB 2.0 wires, are arranged from outer to inner.

Inside the braided layer, there is a layer of black TPE.

And there's a layer of shielding net under it.

The next layer of protection consists of aluminum foil.

Finally, there is another layer of shielding net, served as the negative wires.

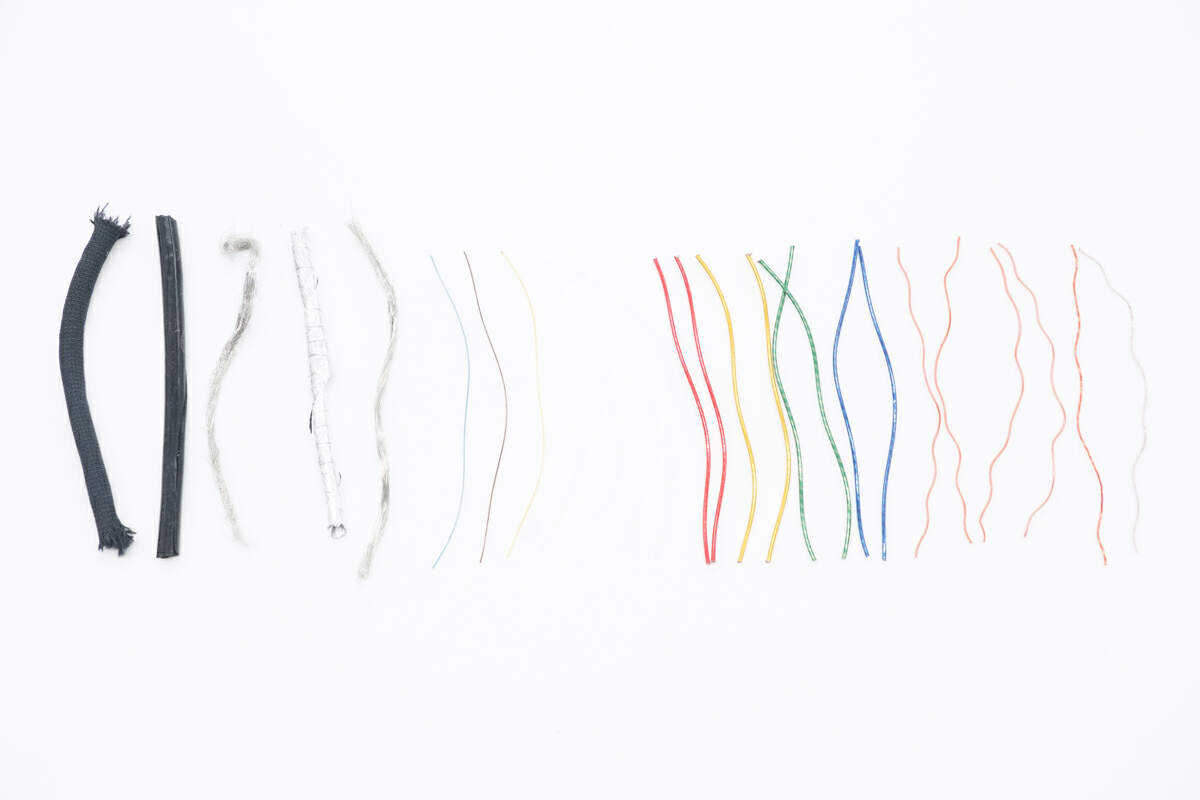

Here is a close-up of the cable's internal structure, including the outer braided layer, black TPE, shielding net, aluminum foil, another shielding net, power wires and data wires. Now, let's take a more detailed look at the wire design inside the cable.

The four positive wires for power supply are made of tinned copper, and there are no tensile fibers.

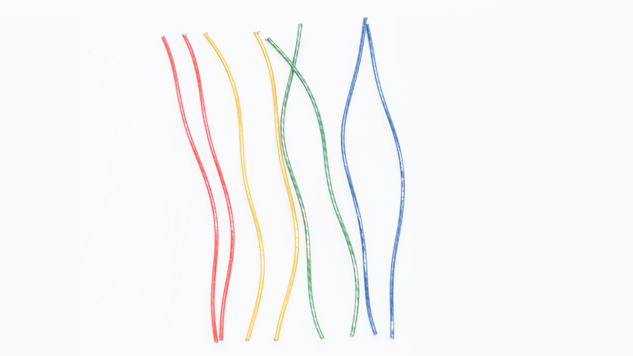

The red, orange, green, and blue wires adopt the same coaxial design, so we take the orange one as an example.

The first layer is a plastic insulating layer, and the copper foil is under it. The most internal wires are plated with silver and wrapped with pure copper shielding plated with silver.

Those two red wires are used for USB2.0 transmission.

And then, the blue wire is CC wire.

The yellow one is Vconn wire.

And the black one is SBU wire.

This is the tensile fibers

Well, that would be all the wires and components of this cable.

Summary of ChargerLAB

Overall, it features two layers of shielding nets and a very thick black TPE outer layer. All of which makes its build quality excellent, even comparable to the 1.8m and 3m versions.

However, as a passive cable, it lacks a series of components inside, including the ReTimer, which is one of the reasons for its lower price. While it does support 40Gbps under Thunderbolt 4, it only supports USB4 Gen2 (20Gbps) instead of USB4 Gen3 (40Gbps). Therefore, this cable is more suitable for users with shorter length requirements and limited budget.

Related Articles:

1. Two ARM CPUs Are Inside | Teardown of Apple Thunderbolt 4 Pro Cable (3 m)

2. The Most Expensive Cable | Teardown of Apple Thunderbolt 4 Pro Cable (1.8 m)

3. Teardown of 240W "DIY" Thunderbolt 4 USB-C Cable